Schedule a Call Back

Automation & robotics industry is expected to grow at 13% CAGR

Industry News

Industry News- Apr 30,22

Schaeffler has been contributing to the growth of industrial automation and robotics sector with right technology products. The company is enhancing its offerings as integrated solution provider and not limiting as a component supplier. In this interview with Rakesh Rao, Sameer Mathur, Chief Operating Officer of Schaeffler India, highlights the importance of automation in the current uncertain business environment and adoption strategy for automated products & solutions.

Are geopolitical tensions and Covid pandemic leading to a VUCA-like situation in the manufacturing sector? (VUCA stands for Volatility, Uncertainty, Complexity, and Ambiguity)

The recent geopolitical tensions and the pandemic is certainly creating increased uncertainty and ambiguity in the market. The major impact that we see in India is additional disruption in the global logistics and supply chain with increased lead times, soaring commodity prices inclusive of raw material. Different waves of Pandemic in India did disrupt the markets and slowed down the overall growth trajectory, but since last quarter 2020, despite the semiconductor crisis, customers are managing a respectable growth momentum in the sectors that we play.

How can automation help Indian manufacturers in this VUCA-like environment?

Forecasting in this volatility and ambiguity is the biggest challenge. Customers change requirements in the month for the month and the swings can be dramatic. To be successful in such challenging environment, organisation must be agile, efficient, and resilient at the same time. Adapting to the change in this VUCA environment is a necessity. It is for organisation to internally to look for solutions rather expecting the customer behaviours to change. Automation possibly is the only solution to steer business in such situations. May it be automation of processes to steer planning and inventory management, may it be automation in the manufacturing arena to utilise the resources with efficiency and agility bringing consistency in processes with benefits of quality, cost, delivery and safety maintaining the morale of the people involved.

How is Schaeffler aiding the adoption of industrial automation and robotics in various manufacturing sectors?

The world is undergoing extreme & turbulent change at an accelerating speed. Innovation, digitalization, and technological progress basically are transforming the industries, reshaping consumer demands, and challenging conventional business logics.

The connectivity between digital technologies, constant collection, and connection of data-points alongside the development of innovative technologies is doubling the speed and capacity while reducing the costs of technology. This again, rises the speed of innovation, digitalization, and technology.

Digitalization in Operation is the need of the hour and we at Schaeffler have digitalisation strategy, encompassing “Digital foundation”, Digital eco system, and digital competence. It works on Digital workplace, cyber physical equipment’s, smart products aligned to the value chain.

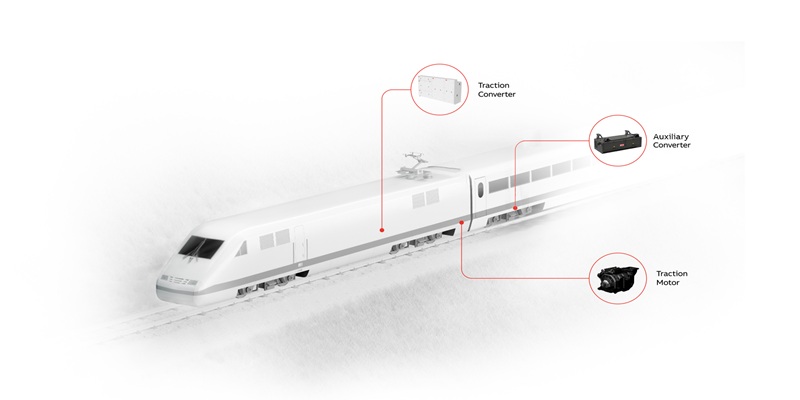

Schaeffler incorporates automated processes coupled with computing intelligence to maintain high precision and reliable manufacturing. Schaeffler has not only adopted industrial automation but also has expertise in manufacturing automation and robotic components. Schaeffler in India has four manufacturing units. Two of our units focus on automotive components while the other two produce industrial products covering sectors such as railways, wind, cement, pulp & paper, iron & steel, and many more. All the four manufacturing plants are equipped with cutting-edge technologies. Schaeffler is Pioneering Motion by implementing Industry 4.0 and is bracing for the next level of industrial automation.

Within the company, how is Schaeffler using some of the advanced solutions to enhance productivity and efficiency?

Schaeffler stand for technology, not just on the product offering but also in the cutting-edge technologies it uses for manufacturing of its products. Schaeffler plants are mostly automated, and we continue to focus on making our plants more efficient and agile using digital solutions. We have many projects running in parallel across all plants focusing on priority topics of the digital roadmap. Projects include use of robots/Cobots AGVs, digital assistant to have paperless office, supervisory control ad data acquisition for heat treatment furnaces and supply systems, extensive use of Augment reality (AR) hallow lens to bring real & virtual worlds together, digital tool set up assistant (DiTOS), digital solution is quality management (COSP- Control of Suspect parts), digital release management, first piece release, extensive use of AI vision systems/Camera for in process/final inspection, digital solution in maintenance (predictive maintenance with condition monitoring, mobile maintenance tools), etc. Finally, we are working on machine connectivity with required infrastructure to utilise big data to steer our operations in future.

In the manufacturing operations, which are the low-hanging fruits that can be automated with least investment?

Complete automation of a manufacturing unit may require big investments. However, it is possible to automate certain areas of the value chain to maximize production and efficiency. With the help of data on time taken by individual processes and the equivalent cost to the company can give clarity on areas to automate. Effective automation varies across companies, based on processes involved and different set standards.

Digitalization and automation project improves “quality”, “cost” and “delivery” and has strategic relevance to organisations considering midterm and long-term view. It positively requires initial investments with short payback. India has always been considered as a low-cost country, and it is for us to harness this benefit to make it a best cost country leveraging benefits of automation and digitalization. There are many processes which are repetitive in nature and could be considered as non-value add processes but inevitable at the same time. Topics like part handling, loading unloading, inspections, packaging etc just to quote a few. There are possible automation solutions which can ensure that this waste can be eliminated.

At Schaeffler digital roadmap and prioritization of projects is defined considering A) value add contribution to the customer and b) Schaeffler Internal benefits in solving challenges. Every project is evaluated with a set framework of a business case. Digital solutions considering machine connectivity and using big data to steer operations is something we are preliminary phase and is a journey that we have just started.

What are some of the emerging trends in industrial automation and robotics?

Industrial automation and robotics are accompanied by emerging trends. These trends help in overall process improvement and propel production capacity. Some of the emerging trends are:

Industrial Internet of Things (IIoT): Interconnectivity of devices is becoming prevalent in all industries. Advancements in the use of sensors and advanced software systems can enable objects to intercommunicate using the Internet and carry out operations without onsite intervention. IIoT is evident among top manufacturers and is essential for quality and productivity success.

Artificial Intelligence (AI): AI is transforming the era of manufacturing by predicting unplanned downtimes and carrying out smooth operations. Artificial Intelligence analyses huge amounts of data also referred to as Big Data to make intelligent decisions. The decisions are based on millions of behavioural studies of the machines.

Asset management: The prevalence of IIoT helps in maintaining company assets. Technology is developing faster than ever. Asset management is possible with IIoT and can be used by manufacturers or add it as a value addition to their products as a service

New technology trends: Many new technologies have come up on the manufacturing horizon:

Cybersecurity concerns: With extensive usage of the internet lay a cloud of cybersecurity concerns. As huge amounts of data are collected and processed in a continuous process environment, security breaches can become common. Companies are constantly working to reduce vulnerability and use some of the most advanced cybersecurity systems.

Will the policy initiatives like PLI schemes, upgradation/modernisation schemes (like textiles, etc), lead to more demand for automated and digitalised products & solutions? Yes, favourable schemes for the industrial sector will lead to implementing automation. As mentioned earlier, automation comes with a cost. It has a gamut of benefits but has a cost attached to it. Favourable policy initiatives will help companies to grow operations and implement automation for absolute process accuracy. This in turn will ensure high-quality standards and competitive pricing - two important pillars in the manufacturing sector.

PLI scheme is to encourage foreign companies to invest in India and encourage domestic and local production for futuristic technologies and generate employment too. Such schemes will possibly help the vendors to explore in new technologies and boost the industry. Automation and robotics industry is expected to grow at a CAGR of 13% in the coming years. The need of robotic and automation solution is there and can only boost the market much more if the required solutions are available in the country.

Related Stories

Where Global Wire and Tube Innovation Comes Together

The world’s leading wire and tube trade fairs return to Düsseldorf, uniting global innovators to showcase AI-driven manufacturing, advanced materials and solutions shaping the future of industria..

Read more

Building the Future of Indian Manufacturing Through Automation

Make in India, industrial automation India, smart manufacturing, AI in manufacturing, Industry 5.0 India, manufacturing GDP growth, robotics and automation, Aatmanirbhar Bharat, Prateek Jain, Addver..

Read more

Why Batteries Trail Strategy in Humanoid Robot Development

Battery makers are racing ahead of robot OEMs in positioning humanoids as the next growth frontier. This press release examines developments from both perspectives and considers how deeper cross-ind..

Read moreRelated Products

Compact Fmc - Motorum 3048tg With Fs2512

Meiban Engineering Technologies Pvt Ltd offers a wide range of Compact FMC - Motorum 3048TG with FS2512.

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.