Schedule a Call Back

Atmanirbhar Bharat: Ramping up the scale of manufacturing

Industry News

Industry News- Feb 21,22

In the last one and a half years, there has been quiet enthusiasm across the country, be it manufacturers, companies to citizens on adopting the ‘Made in India’ products, all thanks to the pandemic. When COVID-19 halted our lives, the global supply chain was badly hit. India faced enough challenges in the procurement of raw material from foreign counties as the supply chain was disrupted due to the closure of international boundaries. Other countries too were in the same situation. This brought businesses across the myriad industry (in every country) to a standstill.

To emerge stronger from the complex situation, the Indian leadership emphasised the necessity of a self-reliant India, and focus towards Atmanirbhar Bharat. This had the power to change India’s mindset towards business functions where we don’t need to depend on others. And, by following the routes, it has immense potential which can turn the tables for us, and boost the GDP growth as well.

Our country has taken up the moment with fervour towards this idea. In many industries, be it pharma, food, e-commerce, and various others, the country has shown in a short span, why the "self-reliant India" approach will be for the betterment of the society.

Though, it may come as a surprise for many, indigenous manufacturing which supported self-reliance of the country, was prevalent since the sixties and the seventies. Paradoxically, where the pandemic had been the source of a crisis, it acted as a catalyst by helping the country in not just revisiting a lost purpose, but also bouncing back with a more constructive and remodelled proposition.

Technology and innovation will be game changers

However, the most important aspect is that India is building its strength in technology and innovation. India is rampantly focusing on Industry 4.0, as it's the need of the hour., It offers immense potential to revolutionise India’s manufacturing and industrial production landscape through Additive Manufacturing (AM) which comprises digital processes, communication, imaging, architecture and engineering that provide digital flexibility and efficiency. Valued in excess of $ 7 billion in 2017, the industry is growing rapidly and is expected to touch $ 35.6 billion by 2023. It will also seek to encourage and promote local manufacturers to seamlessly adopt emerging technologies.

During the pandemic, indigenous manufacturing emerged as the most ideal resort to ensure seamless functioning of the industry without having to rely on external sources for raw material or end products.

Hence, the manufacturing sector is at the forefront. It creates opportunities for the local manufacturers, improving their livelihood which invariably contributes to boosting the overall GDP of the country. Most importantly, localising production can substantially bring relaxation in the expensive duties imposed on imported items. Producing high-quality competitive products can be a gateway for expanding the indigenous business globally.

Focus on digital investments

To achieve phenomenal milestones, manufacturers must be agile enough to approach a new customer base and segments which earlier never showed any signs of reception. The sector needs to ride the Industry 4.0 wave complying with robotics and industrial automation to ensure the effective and continuous functioning of the sector. It will substantially bring down the operational costs and increase workforce productivity. For experiencing unmatched results, the manufacturing industry must focus on digital investments, IT or data centres, technology-oriented supply chains, product or customer growth, efficiency enhancements and also explore new collaborations.

Adopting state-of-the-art digital technologies enables smart manufacturing which makes the entire process easy and flexible. Revolutionary technologies like 3D printing, AI, AR, and robotics will help to cater to the ever-emerging demands of the industry as well as the customers. One breakthrough innovation in this line is AI and IoT-supported robotics. It is endowed with the capability to make decisions in the factory environment which invariably saves time and adds to the productivity of the manufacturers.

For example, during the lockdown automation played a key role in keeping the workforce well-connected and reduced the unnecessary burden of the employees by integrating and monitoring the day-to-day workflow. Companies adopted cloud data with the agility that gave access to real-time information and history of work, helping employees to work anytime from anywhere. It provided comprehensive solutions by keeping track of various operations.

As the manufacturing industry is at the cusp of a radical change, comprehensive initiatives and programs must be conducted for rendering a technologically driven and digitally proficient workforce.

It is time that India realises its true potential and seizes the opportunity to create a global footprint on the manufacturing front. India has already established its position as the largest supplier of drugs globally and is the leading exporter of rice and diamond in the world. Likewise, by bringing about conscious but effective changes in the manufacturing framework, India can capture the global market with its uncompromising, durable, and quality products.

Tax reforms and simple compliances to attract more investors

To ramp up the process of ‘Atmanirbhar Bharat’ government should come up with policies to provide a landscape with the ‘Ease of Doing Business.’ It must not be implemented with the motive to attract foreign investment but must be focused on supporting Indian manufacturers. It must ease the process for local people to do business. See how different countries attract investors. China is leading the league where it not just focuses on large companies but owing to its flexibility, even attracts various medium enterprises from Europe. Investors have even shown an inclination for investing in countries like Thailand and Vietnam.

It is high time that we understand the gravity of the situation and bring about reformatory changes that will fetch lucrative opportunities for the local business. The investors find it hectic to enter into a deal with Indian manufacturers as it takes a very complex route. The entire process involves heavy paperwork, requires one to fulfil innumerable compliances, conduct never-ending audits and comply with many more legal formalities. This discourages any medium-sized company to enter into the business with the country, as they do not have the resources nor energy and it might cost them a fortune to continuously deal with tax consultants and auditors. To eradicate this issue, it is important to see the entire scenario holistically where just reducing the tax rates will not fetch the desired results. The entire procedure must be made simple, transparent and manageable.

As India is spearheading a very bold cause it must start from the very base level. Focusing on establishing the infrastructure will be the first step towards laying the foundation for a self-reliant Bharat. This is not the first time where India is trying to echo her calibre on the manufacturing front. Going back 25 years from today, India showcased promising trends in the hardware industry. At that time, it was in a flourishing stage as compared to China.

Additive manufacturing: The way ahead for Industry 4.0

If the energies are channelised in the right direction, technology is adopted with alacrity, and the challenges thwarting us from achieving the final goal are effectively addressed, then our country can become a manufacturing hub. As countries and companies choose to diversify and recalibrate their supply chains, thus restructuring the global manufacturing order, India is faced with a generational opportunity to strengthen its value proposition and realign its global positioning. Therefore, a strategic effort needs to be undertaken to develop indigenous technological capabilities to fully tap and then leverage the potential opportunities of Industry 4.0. A collective focus on Additive Manufacturing too, can immensely augment India’s efforts to position itself as the manufacturing hub of the world.

About the author:

Deepak Pahwa is the Chairman, Pahwa Group and Managing Director of Bry-Air (Asia). He has over 50 years of experience in engineering & marketing of HVAC&R, air engineering & environmental control technologies. Under his leadership, the Pahwa Group, where innovation is life, has emerged as the fastest growing Adsorption Technology Group in the world.

Related Stories

IMTEX Forming celebrates human ingenuity & machine intelligence: Jibak Dasgupta

In this interview with Rakesh Rao, Jibak Dasgupta, Director General & CEO, Indian Machine Tool Manufacturers' Association (IMTMA), explores trends in the machine tools industry and shares some highl..

Read more

Is your facility ready to handle the energy demands of full automation?

As warehouses scale AI-driven automation, energy demand is emerging as a critical constraint alongside productivity gains. Strategic power planning is now essential, writes Emily Newton.

Read more

Schaeffler Appoints Maximilian Fiedler as Regional CEO Asia/Pacific

Schaeffler has appointed Maximilian Fiedler as Regional CEO Asia/Pacific, effective 1 January 2026, with a seat on the Group Executive Board representing the region.

Read moreRelated Products

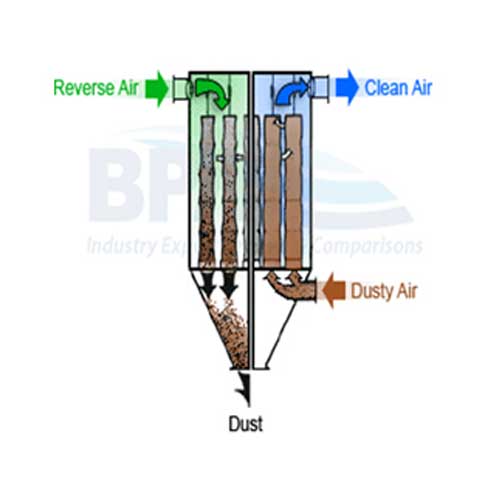

Reverse Air Bag House

ABR Enviro Systems offers a wide range of reverse air bag house.

High Quality Air Knife System

Superchillers offers high quality air knife system. Read more

Compact Cylinders -Vadvu Series

Vijay Air Control offers a wide range of compact cylinders -Vadvu Series