Schedule a Call Back

Atmanibhar Bharat: Revolutionising manufacturing industry

Industry News

Industry News- Feb 10,22

PM Narendra Modi’s flagship ‘Make in India’ initiative was launched to meet three major objectives: to significantly increase the number of jobs by 100 million in the manufacturing sector by 2022; to increase the sector's share to 25% of the GDP; and lastly, to successfully achieve a growth rate of 12-14% annually. The policy’s vision was to eliminate the red tape that hindered any potential inbound investor and to create world-class infrastructure required by the modern manufacturing industry. In addition, the hope was that the policy would encourage a climate that drives innovation and protects property that fosters such innovation. Currently the manufacturing industry’s share of GDP remains under 15% which goes to show the untapped potential that is available for the sector to boost growth.

India has been an independent country with 95% of the manufacturing material sourced locally, and only 5% goods imported for manufacturing. Currently, India’s share of global manufacturing stands at a little over 2%. For India to reach its desired goals and revive the manufacturing industry as well as provide jobs to the tens of millions of unemployed citizens, the need for huge investments from major contributors as well as foreign investors, is vital.

Identifying challenges and potential of the sector

The manufacturing sector has always been essential in boosting economic growth and for the overall development of the country. The nations that export manufactured products tend to have higher marginal GDP growth and also support higher marginal tax revenue and higher incomes. The manufacturing sector is a fundamental source of job opportunities which has the potential to create great social mobility for successive generations.

The growth of the manufacturing sector indeed restores the balance between domestic absorption and domestic production so that an external balance remains controllable. There is a desperate need to formalise jobs in the informal economy. In fact, it also requires long-term, big-ticket investments within large-scale manufacturing businesses. With the government creating and implementing policies in an effort to attract foreign investments to India, the manufacturing sector provided the impetus it had been craving for a while. Today, according to the World Bank's Ease of Doing Business, India’s rank jumped from 130 in 2016 to 63 in 2021. It also moved up from 70 in 2016 to 43 in 2021 in the world competitiveness index.

Way forward in 2022

It has also been observed that to attract domestic and foreign direct investment, there is an urgent need to improve India’s physical infrastructure. India’s manufacturers have a golden opportunity to make the best of this time, to rise from the shadows of the country’s services sector and seize this promising opportunity of the global market. According to McKinsey, the increasing demand in India along with the multinationals’ aspiration to diversify their production in an effort to include low-cost plants in countries, is expected to grow the manufacturing sector significantly by 2025 and also create million domestic job opportunities.

The government initiatives undertaken should include incentivisation to the manufacturing companies. The government of Turkey currently provides facilities to the manufacturing companies which makes them one of the key players in the export market.

Over the decade, most of the country’s manufacturing jobs have disappeared, either due to increase in productivity and automation or even outsourcing it overseas. India is rich in surplus low-skilled labour that must be strategically pivoted to productive employment in non-agriculture urban areas. This will overcome the employment challenge, and help the country meet its inclusive economic growth. Our historical experiences have suggested that the manufacturing sector is capable of absorbing this mass of low-skilled labour into productive employment and this in turn will grow the economy.

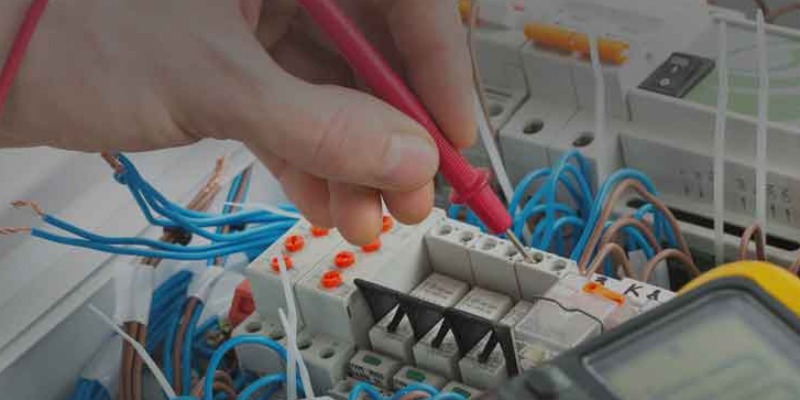

When it comes to the electrical industry, companies should invest in high-speed machinery to increase their production capacity. The government as well as the manufacturing companies should also ensure safety and quality within the wires and cables industry. Digitalisation will improve efficiency and lead to growth. The regulatory initiatives and government schemes like UjwalDiscom Assurance Yojana (UDAY), DeenDayal Upadhyaya Gram Jyoti Yojana (DDUGJY), Integrated Power Development Scheme (IPDS) and Pradhan Mantri Sahaj Bijli Har Ghar Yojana along with booming real estate sector continues to create various business opportunities for the manufacturing and the subsequent wires and cables industry as well. Adding to this, the Transmission and Distribution sector continues to remain in focus and the government's 'Smart City' project is expected to promote large-scale growth across the infrastructure, telecom, power, T&D, engineering and automotive sectors.

The wire and cable industry is directly linked to the growth and development taking place in other sectors which only paves way for an unstoppable tomorrow. Hence, the way forward is right here and it’s time to take action and step up.

About the author:

Shreegopal Kabra is the Managing Director and President of RR Global, a $ 850-million diversified group of industries focusing mainly on infrastructure & electrical solutions spread across 85 countries globally. He is a business leader, philanthropist & global entrepreneur often recognised as a trend setter in the industry. Over the years, he has been bestowed with a number of awards, recognitions and felicitations by various bodies and groups from across the world.

Related Stories

Gandhi Automations Redefines Loading Bay Safety with Dock Levelers

Gandhi Automations strengthens loading bay efficiency with EN-compliant dock leveler solutions.

Read more

India’s Manufacturing Mission: What Make in India Got Right and Wrong

A decade after its launch, Make in India shows sectoral progress but structural gaps remain. As global manufacturing turns VUCA, the next phase must focus on value addition, jobs and ecosystems, say..

Read more

ABB India launches ArTu Formula LV switchgear for safer power distribution

ABB India introduces IEC-compliant ArTu Formula LV switchgear to support diverse applications and India’s growing power needs

Read moreRelated Products

Integrated Electric Gripper S Series

IBK Engineers Pvt Ltd offers a wide range of integrated electric gripper S series.

Geared Electric Motors

Delco Fans Pvt Ltd offers single phase capacitor run and three

phase geared Instrument motors, totally enclosed face/foot mounted.

“Kusam-Keco” Partial Discharge Acoustic Imager - Model - Km-pdai

‘Kusam-Meco’ has introduced a new “Partial Discharge Acoustic Imager Model KM-PDAI.