Schedule a Call Back

AGTOS showcases professional cleaning of castings at GIFA

Industry News

Industry News- Jun 23,15

AGTOS - A Gesellschaft f?r Technische Oberfl?chen Systeme (a company for technical surface technology), showcased current concepts of shot blasting technology for the foundry industry at the GIFA trade fair (June 16-20, 2015 at Dusseldorf, Germany). As far as the machines are concerned, a complete shot blasting plant was on display, which is also suitable for the treatment of aluminium parts. This machine requires a relatively small floor area and is characterised by a low loading height. The loading and unloading process can be carried out both manually and fully automatically.

The topic of service concerns all users of shot blasting machines. Thus, the second main focus was on the turbine technique. By means of assembly demonstrations, AGTOS service technicians demonstrated the advantages of the versatile AGTOS high performance turbines.

The presentation of the quick assembly by means of simple tools provided interesting information for practitioners. The fact that the wear parts of the high performance turbines are available made of different materials showed the flexible application in foundries.

The work pieces to be blasted - the blasting task may be finishing, cleaning or deburring - are placed manually or by using a manipulator onto the wire mesh belt which transports the work pieces through the machine. First of all they pass through the inlet sluice, which seals the subsequently installed blast chamber towards the outside. High-performance turbines installed in the blast chamber are throwing the shot onto the work pieces at a high speed. Thanks to the design of the wire mesh belt the work pieces can ideally be treated with shot from above and below at the same time. At the end of the blasting process, shot and dust are blown off from the work piece surface.

The AGTOS wire mesh belt shot blast plants are designed for highest demands. By means of the installed high-performance turbines an optimum covering of the surface is achieved. This guarantees short blasting times and high-quality blasted products. The automatic abrasive dosing device installed above the turbines ensures that blasting only takes place when there are work pieces in the blasting area. This minimizes the wear of the shot blast plant. A blower unit removes any shot remaining on the work piece surface.

AGTOS, Germany. Tel: +49 (0)2572-96026-0. Fax: +49 (0)2572-96026-111. Email: info@agtos.de

Related Products

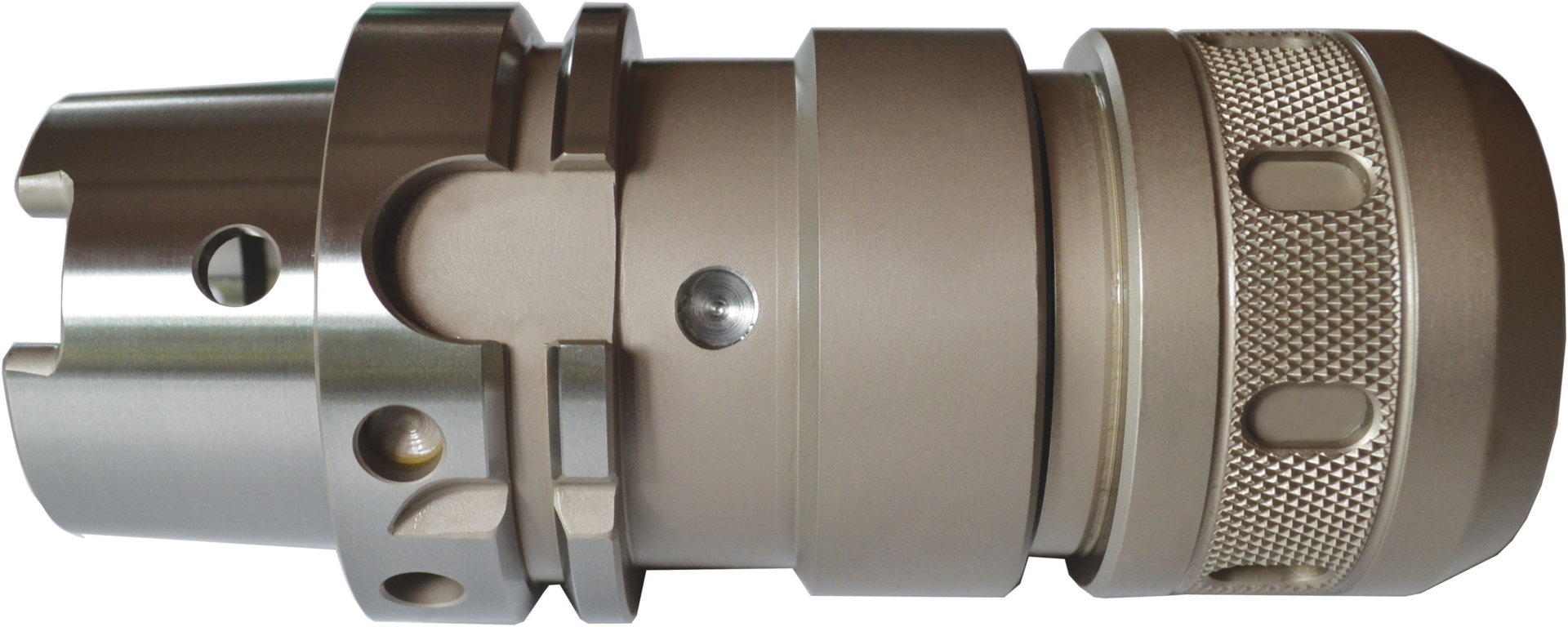

Hi-power Milling Chucks

Bilz Tool

offers a wide range of hi-power milling chucks.

Spur Gears

Shubham Gears is engaged in offering a comprehensive variety of spur gears.

Commutator Motors

J D Automation provides a range of commutator motors, which are also

known as permanent magnet DC motors.