Schedule a Call Back

Schmersal to showcase world’s smallest electronic solenoid interlock at SPS

Industry News

Industry News- Nov 19,19

Related Stories

Salvagnini Italia Hosts Global Doors & Frames Industry Leadership Meet

Executives from 20+ countries met in Italy to discuss automation, flexibility and manufacturing complexity in doors and frames.

Read more

Manufacturing Excellence in the Age of Integrated Automation and Industry 4.0

Manufacturing leadership is shifting from scale-driven efficiency to integrated, data-led systems that deliver resilience, sustainability and enterprise-wide performance through Industry 4.0 and aut..

Read more

End-of-Line Automation in an Era of Volatile Manufacturing Operations

Manufacturers face labour volatility, stricter compliance, and rising delivery expectations, making resilience as critical as efficiency. End-of-line automation is emerging as a strategic foundation..

Read moreRelated Products

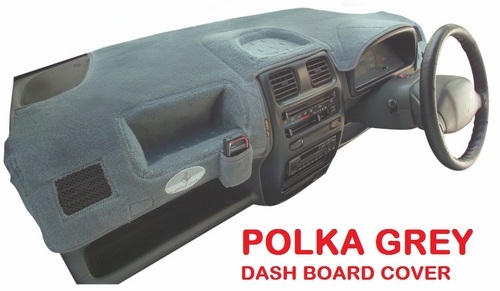

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.