Schedule a Call Back

Sawalka KEL is first to make Nitrile-dipped gloves in India

Industry News

Industry News- May 04,20

Due to the Covid-19 outbreak, industries are forced into the lockdown. Hoping for a positive sentiment, government may consider opening up industrial operations selectively. In a video interaction, Pratap Padode, Editor in Chief of Industrial Products Finder (IPF), spoke to Avinash Sawalka, Director, Sawalka KEL, about current situation and readiness of the company to resume operations.

Tell us how you serve industry with your products?

We are an engineering company manufacturing various engineered products. We started our industrial safety division 10 years ago. Since then we have been selling specialised safety gloves for the automotive industry. SawalkaKEL is a tie-up with KEL worldwide which is an Indo-French joint venture. While all the products in India are sold under brand name KEL Safety. We supply our safety gloves to specialised and focussed industrial segments such as automotive engineering, metal engineering, automotive tier-I and tier-II companies, tyre and rubber industries.

Our products are known for its features like cut, heat and abrasion resistance. We give very long performance standard, and very good conformity to European Standards (EN). Almost all our gloves are certified as per the EN norms which are lately upgraded.

Could you tell us about effect of the current situation on your operations?

We have encountered that the slowdown hit us in patches. During the first and the second week of March, we saw slowdown in Pune, Maharashtra area. It further moved to Gujarat and the Northern India region. Finally, it also affected Southern and the Eastern regions.

When we entered lockdown on March 23, we still had shipments going to our customers and our customers were still demanding products.

End of the March was the primarily output time for almost all automotive companies and they were also pushing the numbers as they had good demand coming in. Many companies kept their capital purchases at the end of the year. This got affected severely. We too had our cargo lying inside trucks and unable to enter warehouses.

A lot of stock that we kept ready for end-of-the-year needs, although we were cautious but yet you have to be ready to supply it to your customer when the year end is approaching. At the moment, it is wait and watch to see how and when the government wisely decides to open up industrial activities and we are ready as soon as the operation resumes.

What is your plan for resuming your operations?

We are ready and will start as soon as government announces as most of our labourers are based out locally. Even our customers will get their material easily as we have warehouses located strategically located near the auto, engineering clusters and near our customers. Our customers are mostly OEMs and we supply more to B2B businesses and not through our distribution channels. Our warehouses are well stocked.

What is your current inventory position to serve your customers?

We can supply for 2 months if industrial operations resume. Though it depends entirely on the offtake of the customers. It is to see what will be our customers approach, whether they will start phase-wise starting their manufacturing by initially by 30 per cent, 50 per cent, 100 percent. If customers go for a phase-wise approach, we can surely sustain in comfort and for long. On the contrary, if they go for 100 percent of operations then we will be able to serve them for almost 2 months.

Do you also supply your PPE gears for the medical segment in the wake of Covid-19?

Most of our customers are into engineering domain and we are industrial engineering PPEs. We are specialised towards protecting hand, sleeves and arms safe from machines, sharp objects and surfaces in engineering environments. For example; these gears are used in automotive industries where panels are of 0.3-0.5 mm thickness.

That being said, we do have disposable products that we supply to medial and food industry. Though these are not very large parts of our operations and mostly these are our customers who have availed our other engineering solutions. Special glove requirements for these customers are served by us like chemical or FDA approved medical gloves.

What is your composition of domestic sales to exports?

Our Indo-French JV company is an Export Oriented Units (EOU) company and SawalkaKEL takes care of domestic operations. We contribute to a share of about 20-25 per cent of total turnover of the entire group. Our 20-25 per cent contribution can be attributed to domestic sales while 70-80 per cent towards exports.

With the advent of automation do you see that the demand of the industrial engineering gears has increased?

The overall effect over industry segment is that the people on shop floor will be less compared to manual sites. Firstly, there are certain jobs which will require human interventions like those of painting and welding.

Secondly, in India, while big industries move towards automation, there will also be a rise in use of certified-PPE products which is not a usual practice in smaller industries. People are using cotton gloves right from welding, painting and across all jobs. This is due to absence of legal industrial guidelines in India. These guidelines are established in Europe for every job.

Thirdly, on cut-level gloves we have got some products that work with automation as well. These gloves are also offering easy access to use smartphones or tablets or touchscreens.

Tell us about your solutions for construction sector?

We do have products for welding, cement or brick work but lot of unorganised labour and contract labour which is now improving. With regard to safety shoes, almost all construction companies are using standard shoes while we see a very less offtake on the safety gloves segment. There are a few construction companies who work with us to ensure they are using certified gloves and sleeves.

Unless this is used in the legal framework, the offtake for gloves and sleeves in the construction segment seems to be a challenge.

Any plans on expansions?

We have a 3-5 year of expansions planned. We currently have 3 plants in Kolkata. We have recently added our 4th plant in Ahmedabad. This new plant will have extra lines for production and we are first to have Nitrile-dibbing in India, which is a coating on gloves offering features such as dexterity, abrasion, use of gloves on oily surface.

Indian companies are involved in Polyurethane-dibbing. Nitrile-dipped gloves are currently imported in India while we are first company to provide Nitrile-dipped gloves on the palm side of the gloves.

Related Stories

PLI scheme: Need for a course correction

The Government of India is reportedly planning to ease some norms for five sectors (textiles, pharmaceuticals, drones, solar and food processing) to help them better utlise the fund under its Produc..

Read more

Cleaning and hygiene are must to ensure safety of products

In this interview, Samir Sabu, Director, Soma Specialities Pvt Ltd, explains how mechanised cleaning helps these process industries adhere to stringent manufacturing norms and produce high-quality p..

Read more

Seven material handling equipment trends to watch out

The development of more environmentally-friendly machines that reduce energy consumption and increase efficiency will be a key driver of innovation, says a Freedonia Group report.

Read moreRelated Products

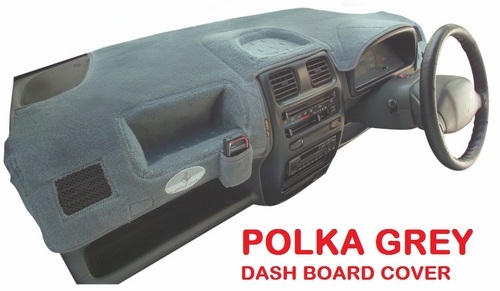

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.