Schedule a Call Back

Renishaw to showcase smart factory solutions at IMTEX 2019

Industry News

Industry News- Jan 22,19

Related Stories

Revolt Motors Welcomes Roy Kurian as President to Lead Future Growth

Revolt Motors reinforces its commitment to global leadership, aiming to be India’s No.1 electric motorcycle brand and a major player in sustainable mobility worldwide.

Read more

Hydrogen Pipelines: Key to India’s Clean Energy Future

India is taking significant strides towards clean energy, positioning itself as a global leader in the green hydrogen revolution. Nikhil Mansukhani, MD, MAN Industries India Ltd, discusses the role ..

Read more

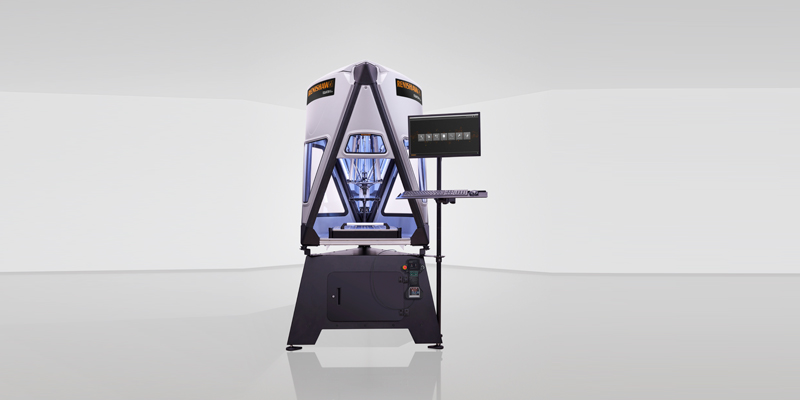

Renishaw Unveils Equator–X 500 Dual-Method Gauging System

Equator–X 500 dual-method system extends the Equator range of versatile gauges for shop floor process control, high-speed measurement and quality assurance

Read moreRelated Products

Precision Cutting Tools1

S S Trading Corporation offers a wide range of precision

cutting tools.

Slotting Head Unit for All Cnc Turn Mill Centers

Sphoorti Machine Tools Pvt Ltd offers a wide range of

slotting head unit for all CNC turn mill centers.

Slotted Tool Disc and Tool Holders

Prominent Machine Tools offers a wide range of slotted tool disc and tool holders.