Schedule a Call Back

GE Additive unveils first BETA machine from its Project A.T.L.A.S program

Industry News

Industry News- Nov 15,17

Related Stories

Daikin to expand compressor manufacturing to two million units in India

Daikin is also exporting to markets such as South Africa, the Middle East and South America helped by its new 75-acre Sri City manufacturing unit.

Read moreSuper Screws and Mitsuchi Corporation to manufacture cold forged parts in India

The new venture will set up a manufacturing plant in India to produce and distribute high-quality cold forged parts, catering to both the Indian market and global exports.

Read more

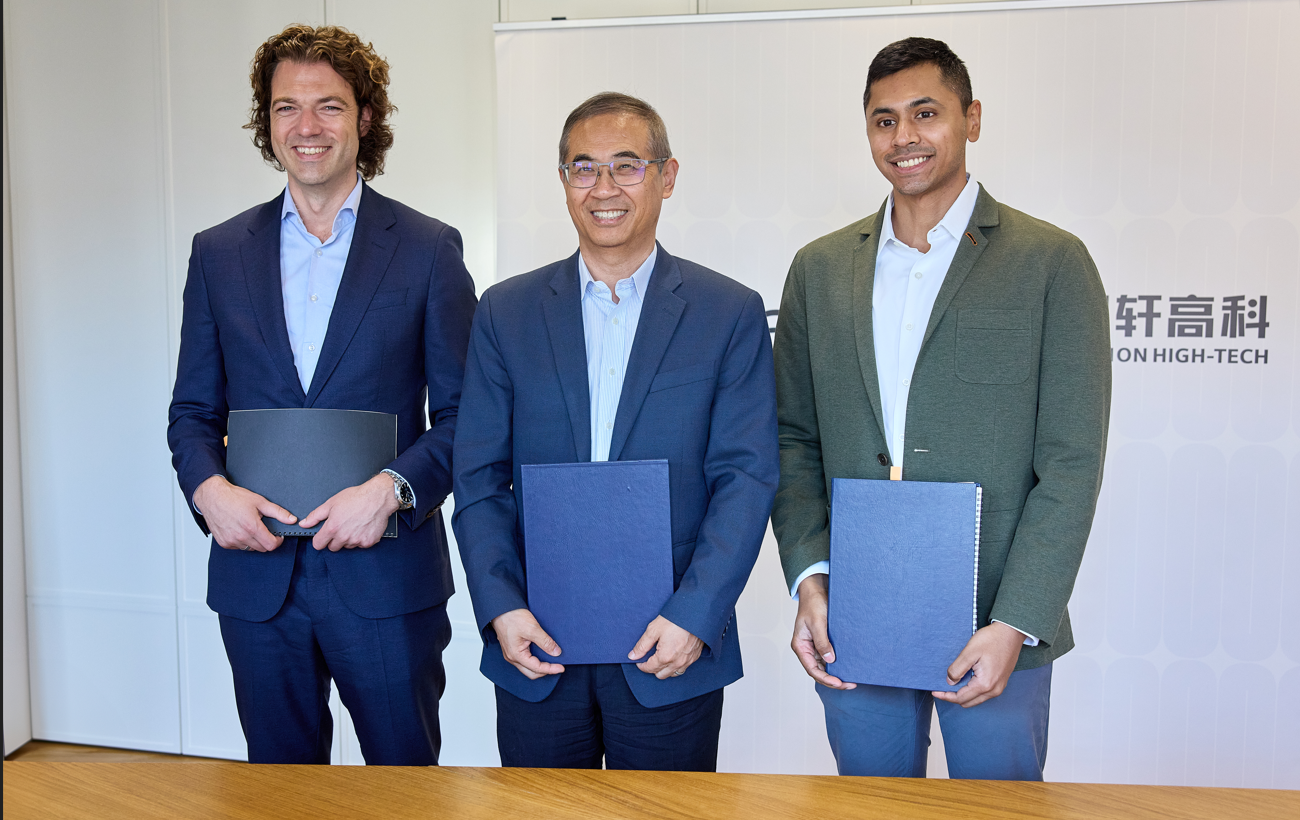

Amara Raja announces partnership with Gotion-InoBat-Batteries

The technology transfer and service support will fully complement Amara Raja’s efforts to operationalise its Gigafactory manufacturing capacities.

Read moreRelated Products

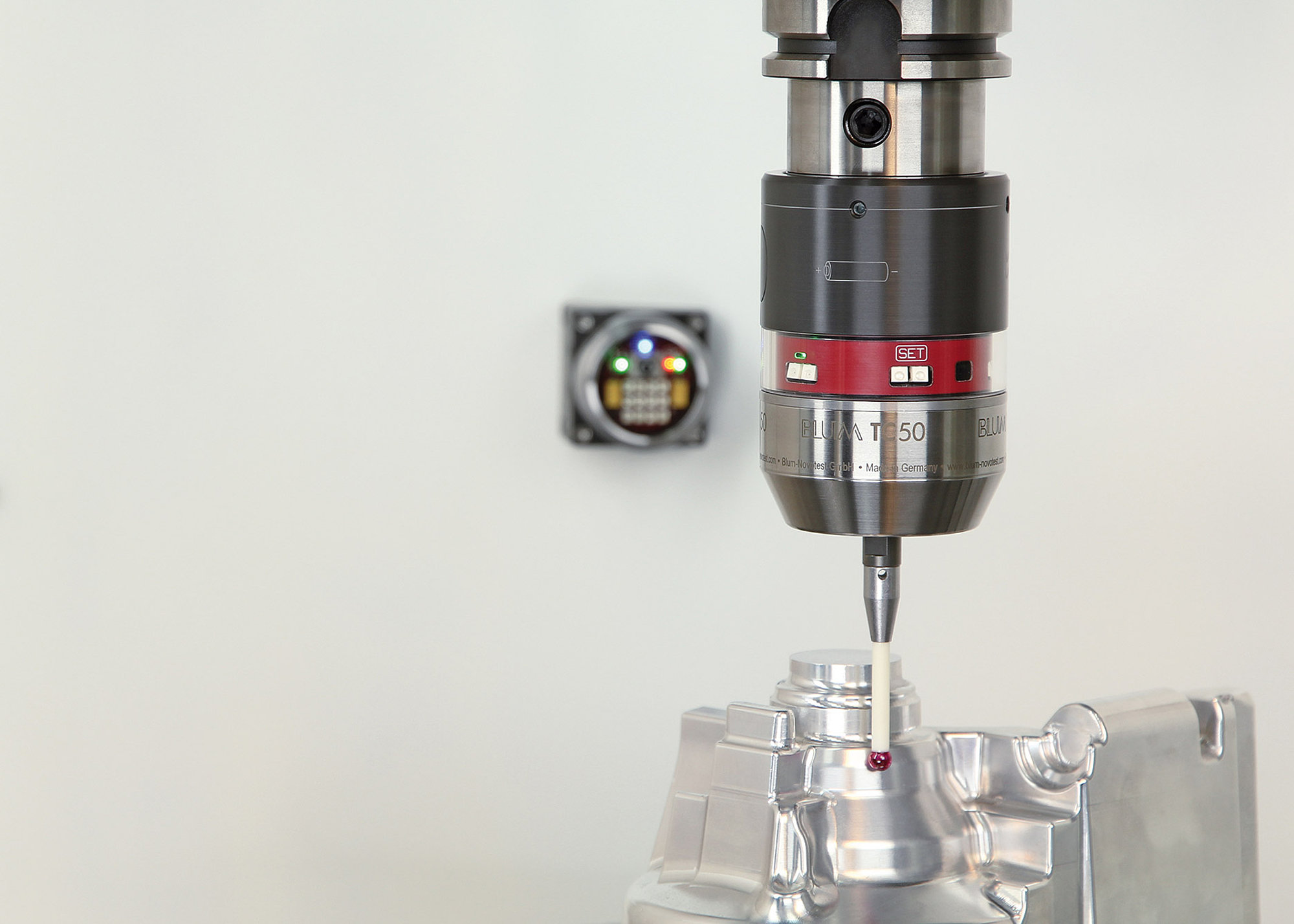

Measurement Software

Blum-Novotest Measuring & Testing Technology Pvt Ltd offers a wide range of measurement software.

Twincat Controller Redundancy Software

Beckhoff Automation offers TwinCAT Controller Redundancy – the software-based solution protects plant uptime through redundant control operation.

Software System

Beckhoff’s TwinCAT CNC offers the option to implement interpolation with up to 32 simultaneously interpolating axes.

Read more