Schedule a Call Back

EMAG ECM showcases E-mobility solutions at Technology Day

Industry News

Industry News- Feb 01,19

Related Stories

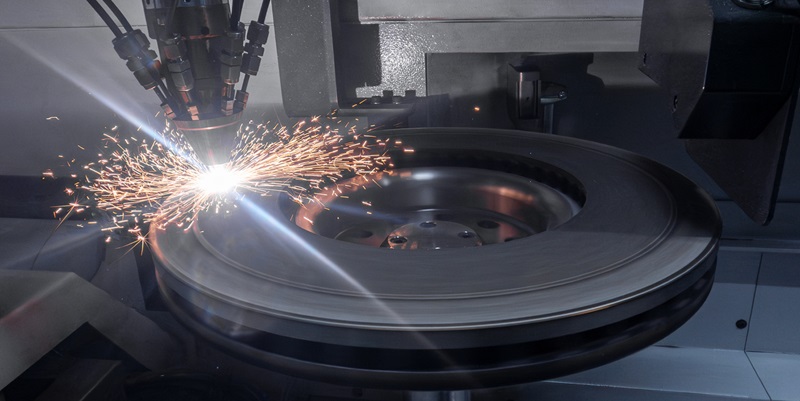

Low-emission brake disk: Best practice in data-driven production

Eurozone's decision to equip new car models with low-emission braking systems from next year represents a technological leap for the manufacturing industry

Read more

Low-emission brake disk: Best practice in data-driven produc

Eurozone's decision to equip new car models with low-emission braking systems from next year represents a technological leap for the manufacturing industry.

Read more

EMAG’s efficient solution of coating brake discs

EMAG’s solution is economical, suitable for large-scale production, reliable and variable, as a variety of material combinations can be used for coating.

Read moreRelated Products

Commutator Motors

J D Automation provides a range of commutator motors, which are also

known as permanent magnet DC motors.

Compact Speed Vector Drives

Confident Automation offers compact speed vector drives.

Microstepping Motor Driver

Yugandhar

Systems offers a silent microstepping motor driver – YSSPD 4.