Schedule a Call Back

Improving patient outcomes with smart implants

Technical Articles

Technical Articles- Mar 01,18

Related Stories

GE Aerospace boosts Pune unit with USD 14m upgrade

GE Aerospace is investing USD 14 million to expand and modernise its Pune facility, strengthening manufacturing capability and supporting advanced engine component production.

Read more

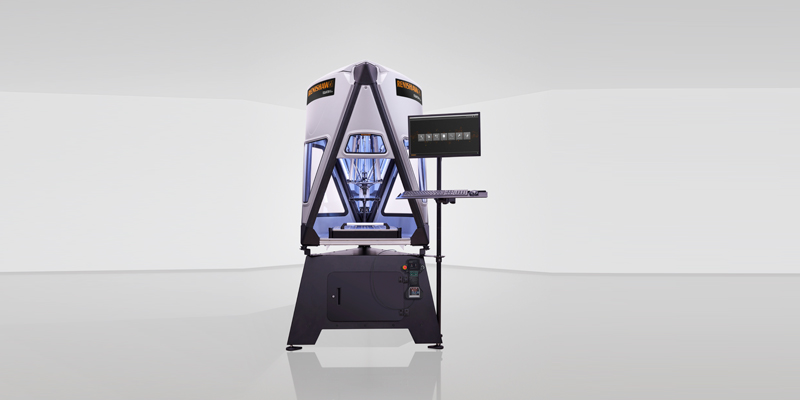

Renishaw Unveils Equator–X 500 Dual-Method Gauging System

Equator–X 500 dual-method system extends the Equator range of versatile gauges for shop floor process control, high-speed measurement and quality assurance

Read more

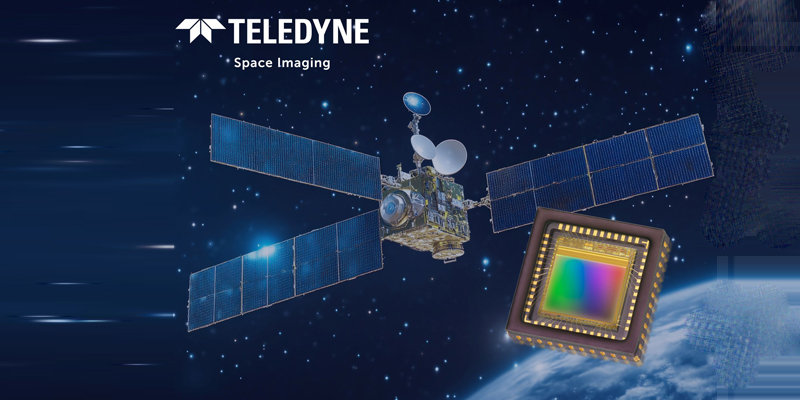

Teledyne Launches Industrial Image Sensors for Space

These new products complement Teledyne’s ongoing offerings for demanding science and defense missions by providing options for the less rigorous New Space market.

Read moreRelated Products

Heavy Industrial Ovens

Hansa Enterprises offers a wide range of heavy industrial ovens.

High Quality Industrial Ovens

Hansa Enterprises offers a wide range of high quality industrial ovens. Read more

Hydro Extractor

Guruson International offers a wide range of cone hydro extractor. Read more