Schedule a Call Back

Electrical safety hazards in the workplace

Industry News

Industry News- Apr 29,22

Electricity is one of the most vital resources that is leveraged at any workplace globally. It is used in every aspect in today’s modern workplaces – right from a construction site to a high-tech office. Since electricity is so omnipresent at workplaces, if electrical equipment, appliances and installations are not maintained well, the consequences can be devastating.

In India, faulty electric wiring and appliances are one of the most common causes of fires in industrial and commercial premises, accounting for 5,000-6,000 (20%) of the 25,000-30,000 non-residential accidental fires. The Central Electricity Authority (CIA) data attributes nearly 40% of deaths at workplaces to electrical issues.

Workplace accidents report nearly 13 electrocution deaths on an average day in India. This is the highest in the world. The annual average of electric-related deaths in the UK and the United States is 8 and 82 respectively.

The CEA says 42% of the fires are due to faulty electrical systems. Majority of the short-circuit fires are triggered by improper wiring, poor electrical fittings and bad maintenance of wires. World over, deaths and injuries arising from electrical hazards at work are a result of poorly maintained electrical equipment, or people coming into contact with electricity while working near overhead power lines or underground cables. In fact, working close to machines, equipment, and tools that are connected to power lines may also be fatal due to the lack of circuit interrupters. There are several other common causes of injury too. These include working near live wires or electrical equipment and using unsuitable electrical equipment in a flammable or explosive atmosphere, where a spark from the equipment triggers a fire or explosion.

In constructions sites in India too, electrocution is a common cause of deaths of workers. According to data, of the 1,092 deaths that occurred on constructions sites in the country between 2013 and 2016, 15% were due to electrocution. Construction sites are often a work in progress, which means there is exposed wiring, power lines, and unfinished electrical systems around. Electrocution among workers could occur while using hand tools or carrying our electrical work. In most cases, there are various hazardous situations like the site is damp with pools of water, the electric saw is not properly earthed, the power socket is not fitted with a residual current device, leakage is not checked from the electric saw, the power supply is not disconnected before the work is carried out or insulations of some of the wires has been damaged.

The exact effect of an electrical shock or injury will depend upon a number of factors, including the size of the voltage, which parts of the body are involved, whether the person is in contact with water or moisture and the length of time the current flows etc.

In India, it is required that all electric installation work should be carried out in accordance with the National Electricity Code and various codes of practices issued by the Bureau of Indian Standards (BIS). However, many workplaces and construction sites do not follow them in their entirety. While the National Building Code 2016 tackles issues related to fatalities caused due to short circuits and lists regulations to prevent electrical hazards, there is a major lack of awareness about its implementation. A general laxity in following norms has been responsible for the apathy towards safety to be followed while laying out electrical installations.

Compare this with countries like the UK where employers are required to have a general duty under UK health and safety law to ensure the health and safety of their employees and anyone else who could be put at risk by their work activities. This includes protecting workers and others from risks arising from the use of electrical equipment and work on or near electricity, such as a building’s wiring, electrical equipment such as machinery, below ground cables and overhead power lines.

In India, accidents that occur at places like construction sites or other sectors cause scant alarm. They do not give rise to measures to ensure greater safety. This is because often little or no official record exists of the deaths of workers in construction. In fact, what is alarming is that compliance with the National Electricity Code is voluntary rather than mandatory in India.

In the UK, meanwhile, the Management of Health and Safety at Work Regulations 1999 require employers to assess all significant health and safety risks and to make arrangements to adequately control risks to people’s health and safety arising from work activities. India could take some lessons from the UK when it comes to electricity at workplaces. The Electricity at Work Regulations in the UK, among other things, requires employers to ensure that anyone carrying out work on, with or near electrical systems, equipment and supplies has the necessary competence to prevent injury to themselves and to others. As per the regulations, employers are required to identify the hazards and assess the risks from electricity at work. They should then take appropriate precautions to protect their workers and others from the risk of being injured.

The picture could improve slowly in India with organisations like the British Safety Council (BSC) who are trying to bring in more awareness about issues like workplaces safety.

About the author:

Hemant Sethi is the Country Head India of British Safety Council India. BSC is challenging traditional approaches, and aiding employers in adopting practices that safeguard the health and safety of their workers. BSC has been striving to bring about a culture change with regard to workplace health, safety and wellbeing.

Related Stories

The Growing Threat of Heat Stress in the Workplace

Extreme heat puts millions of workers at serious risk globally. Suresh Tanwar, Senior Head of Audit and Consultancy, British Safety Council, India, highlights the growing threat of heat stress in th..

Read more

Enhancing safety in high-risk industries: Suresh Tanwar

Similarly, it is crucial to invest in the training of the workforce and safety awareness. Safety must commence on the first day of employment, irrespective of the type of job or contract, remarks Su..

Read more

Unlocking the power of Behaviour Based Safety in workplaces: Suresh Talwar

A solid Behaviour-Based Safety Programme is crucial for boosting safety performance and keeping employees committed to staying safe.

Read moreRelated Products

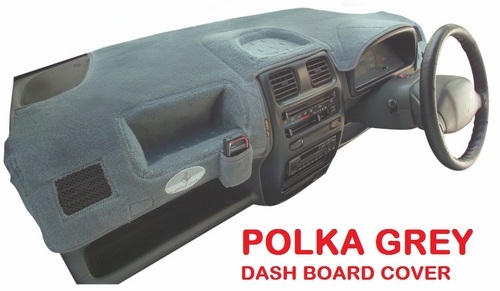

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.