Schedule a Call Back

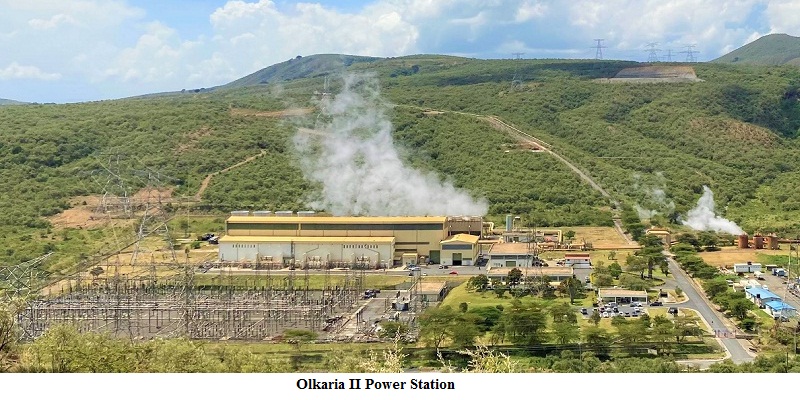

Yokogawa installs IoT system at Kenya’s Olkaria Geothermal Complex

Industry News

Industry News- Sep 12,22

Related Stories

Increasing automation drives servo motors demand

The market for servo motors was significantly influenced by the growing use of automation across a number of industries, including manufacturing, automotive, electronics, and packaging, says Adroit ..

Read more

Waste pooling collaboratives for profitable circular economy

Waste reduction is one of the key steps towards sustainability. Companies opt for recycle, reuse and refurbish waste to create value. Here, R Jayaraman explains the concept of waste pooling collabor..

Read more

RAHSTA to showcase cutting-edge road construction tech, says NCC Director

14th RAHSTA (Roads and Highways Sustainable Technologies & Advancement) Expo - India’s biggest road exhibition - will be held as a part 10th India Construction Festival 2024 at Jio Convention Cent..

Read moreRelated Products

Industrial Desalination System

Shakunth Aqua Products offers a wide range of industrial desalination system. Read more

Industrial Castors & Wheels

H M Gulamali offers a wide range of castors and wheels manufactured by Blickle, Germany. Read more

Foxconn, Nvidia join forces for AI factories revolutionising tech production

Taiwanese technology giant Foxconn and leading US hardware company Nvidia revealed their partnership to establish "AI factories," advanced data processing centres geared toward driving the production Read more