Schedule a Call Back

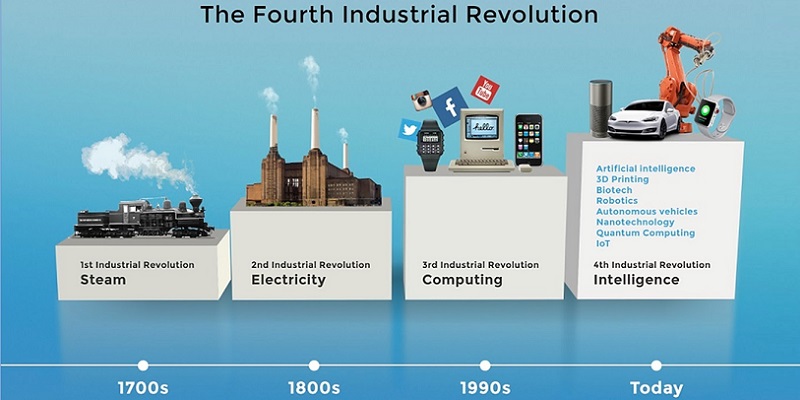

Vivek Sharma: Data is the new currency

Interviews

Interviews- Jul 14,21

Related Stories

Schneider Electric to automate Mumbai’s Bhandup water treatment plant

This upgrade will make the Bhandup facility a critical part of India’s largest single water treatment complex, with a total capacity of 4,500 MLD.

Read more

Mahindra unveils EV manufacturing & battery assembly facility in Maharashtra

Mahindra has allocated Rs 45 billion out of the total Rs 160 billion planned in the F22–F27 investment cycle— which includes powertrain development, two product top hats including software & tec..

Read more

A new future: The advent of a ‘provice’

This is a new era, where each product is a combination of product and service, and hence, there is an urgent need of a new term for this new creature. My choice is ‘provice’, till a better name ..

Read moreRelated Products

Standard Series Stations and Enclosures

Esbee

Industrial Combines/Esbee Electrotech LLP offers standard series stations and

enclosures.

Fire Alarm

Safe Zone is prominent traders and suppliers of the industry, offering a wide range of wireless fire alarm.

Read more

Sorting Automation Systems

Renovus Vision Automation offers sorting automation systems.

Read more