Schedule a Call Back

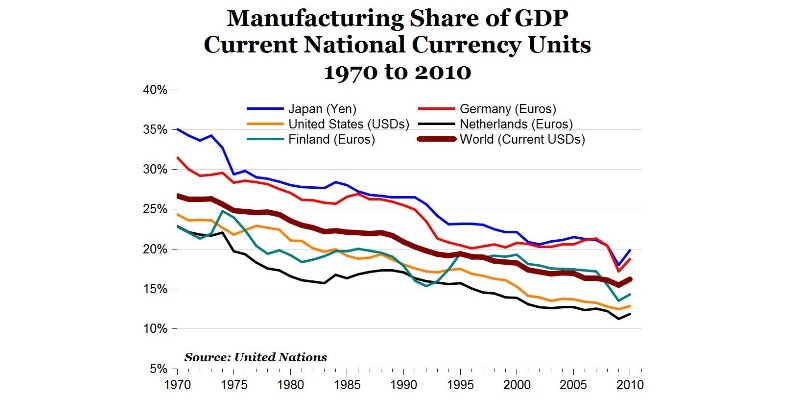

The changing world of manufacturing

Articles

Articles- Dec 10,21

Related Stories

Haber Unveils AI Green Chemistry Lab in Pune

The lab features an integrated pilot plant, allowing scientists to replicate large-scale manufacturing processes in a controlled environment.

Read more

Why Precision Tooling is the Backbone of India’s Next Manufacturing Leap

If manufacturing is the body, tooling is the skeleton holding it all together. Dr Dario Maria Fumagalli, President & CEO, Silmax, believes, for India’s rise as a global manufacturing hub, tooling ..

Read more

Taiwan Smart Manufacturing Pavilion spurs India–Taiwan collaborations

Over the course of the exhibition, the Pavilion recorded over 100 industry visitors and engaged with 85 potential buyers, demonstrating a high conversion rate of interest into tangible business lead..

Read moreRelated Products

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.

Heat Exchanger Scale Removal Compound -hesr-300

Hi There!

Now get regular updates from IPF Magazine on WhatsApp!

Click on link below, message us with a simple hi, and SAVE our number

You will have subscribed to our Industrial News on Whatsapp! Enjoy