Schedule a Call Back

Schmalz enhancing automated material handling

Industry News

Industry News- Mar 26,25

Related Stories

IIT Hyderabad and Deakin University launch AMRIT to advance smart manufacturing

The initiative is set to drive research excellence in key areas such as additive manufacturing, smart materials, lightweight composites, automation, and Industry 4.0 technologies, while also helping..

Read more

Automation Studio Code offers a new automation engineering experience

This development plug-in is perfectly integrated into Automation Studio 6 and makes working on a project with two tools possible without any migration required ¬¬¬¬, fully compatible and flexibl..

Read more

India is a key strategic market for Hexagon: Jason Walker

In this interaction with Rakesh Rao, Jason Walker, VP, General Manufacturing Practice Lead, Hexagon, sheds light on the factories of the future and importance of India for Hexagon.

Read moreRelated Products

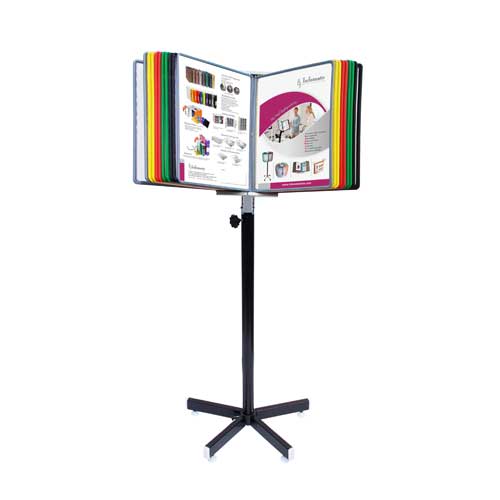

Dna of All Information

Roto Leaner Technology Pvt Ltd manufactures a complete range of display solutions.

Standard Series Stations and Enclosures

Esbee

Industrial Combines/Esbee Electrotech LLP offers standard series stations and

enclosures.

Fire Alarm

Safe Zone is prominent traders and suppliers of the industry, offering a wide range of wireless fire alarm.

Read more