Schedule a Call Back

India: A Manufacturing Perspective: Kamlesh Panchal

Articles

Articles- Feb 07,25

The ‘Make in India’ initiative has positioned India as a global manufacturing hub, fostering innovation, sustainable practices, and advanced manufacturing technologies. As part of this transformative journey, many companies have contributed significantly by investing in state-of-the-art facilities and adopting strategies to meet the growing demands of both domestic and international markets. The dynamics of ‘Make in India,’ including strategic investments, green manufacturing, advanced technologies, and people management—basic pillars for propelling India's manufacturing growth.

Strategic investments and government policies

India’s manufacturing landscape is rapidly evolving, thanks to strategic initiatives and supportive government policies. Government policies, such as the Production Linked Incentive (PLI) schemes and Make in India initiative, are designed to encourage domestic manufacturing, attract foreign investments, and foster innovation. Companies are leveraging these opportunities by making substantial investments, such as establishing state-of-the-art factories and production facilities. These facilities not only aim to cater to the growing Indian and export markets, but also underscore sustainability through environment care initiatives. Companies who align their plans with these government-backed initiatives are paving the way for India to become a leader in both industrial innovation and sustainable manufacturing. Realising India's potential as a global manufacturing powerhouse will require cooperation between the public and private sectors. We need to accelerate digitisation to increase export and production mechanisms' scalability, efficiency, and transparency.

Low carbon manufacturing: Towards a sustainable future

Sustainability is no longer optional; it is a necessity for modern manufacturing. Companies must integrate eco-friendly practices that align with the company’s science-based targets and low-carbon economy goals, focusing on waste reduction and the use of renewable energy sources such as solar power, green energy, and rainwater harvesting to minimise their environmental impact. By prioritising sustainability, manufacturers not only reduce the amount of carbon footprint but also promote energy efficiency, and circular economy principles.

Emerging markets for Compressed Natural Gas (CNG mobility) biogas, hydrogen, and carbon capture usage and storage via CO2 compressor technologies highlight the shift towards alternative energy sources. Companies are increasingly developing energy-efficient products, such as variable speed drive compressors that reduce energy consumption by up to at least 20 per cent. These innovations not only benefit customers by lowering operational costs but also contribute to a cleaner environment.

India’s potential in green manufacturing is vast. With global investment flowing into renewable energy and sustainable technologies, Indian companies have the opportunity to establish themselves as leaders in this domain. By prioritising eco-friendly practices and adopting international sustainability standards, Indian manufacturers can enhance their competitiveness on the global stage.

Advanced manufacturing technologies

The adoption of advanced manufacturing technologies is revolutionising India’s industrial ecosystem. Industry 4.0 initiatives, including automation, robotics, digitalisation, and AI/ML applications, are becoming integral to manufacturing processes. We as manufacturers exemplify this trend by incorporating cutting-edge technologies in the manufacturing factory to boost productivity and meet global standards.

The company’s focus on emerging technologies such as additive manufacturing, energy conversion solutions, and waste heat recovery systems reflects the growing importance of innovation. Establishing dedicated heat labs and high-tech testing facilities further enhances product development and validation, ensuring superior quality and performance.

India’s push for advanced manufacturing technologies is supported by government schemes promoting digitalisation and innovation. The integration of smart technologies not only improves efficiency but also enables manufacturers to respond more effectively to market demands. Moreover, by leveraging data analytics and IoT, companies can optimise their supply chains and reduce operational costs.

People handling

A robust manufacturing ecosystem requires a skilled and diverse workforce. To build a skilled workforce a comprehensive people management strategy is required. This involves implementing on-the-job training, upskilling initiatives, fostering a culture of continuous learning, career development pathways, digital literacy training to engage employees with the evolving manufacturing landscape. These programs empower them with the latest technological know-how, fostering innovation and operational excellence. This collaborative approach between industry and academia ensures a continuous supply of skilled talent.

India’s demographic advantage offers a significant opportunity for workforce development. By investing in upskilling and reskilling initiatives, companies can bridge the skill gap and ensure a steady flow of talent. Collaborative efforts between industry, academia, and government are essential to create a future-ready workforce equipped to handle the demands of advanced manufacturing.

Challenges and opportunities

Despite significant progress, India faces challenges in becoming a global manufacturing leader. Infrastructure gaps, energy reliability, and regulatory complexities are areas that require continued focus. However, initiatives like the Goods and Services Tax (GST) and increased FDI inflows are paving the way for a more conducive business environment.

The growing emphasis on sustainability and advanced technologies presents enormous opportunities. India’s knowledge-based sectors, such as IT and pharmaceuticals, combined with its burgeoning manufacturing capabilities, position the country as a strong contender in the global market. With continued investments and policy support, India can achieve its goal of contributing 25 per cent to GDP through manufacturing.

Contribution to the GDP

Among fast growing countries, the contribution by the manufacturing sector to the GDP, stands at over 30 per cent; this remains a benchmark for global manufacturing. However, India is making significant strides, with manufacturing contributing approximately 20 per cent to its GDP. India’s infrastructure investment shows a good pace and growth due to recent reforms and several initiatives are closing the gap.

India’s strengths lie in its knowledge-based industries, robust financial markets, and a thriving private sector. The ‘Make in India’ initiative is bridging the manufacturing gap, with a focus on export-led growth and technological innovation. By leveraging its demographic dividend and emphasising skill development, India can further enhance its manufacturing capabilities.

India’s rising competitiveness in sectors like automotive, electronics, and renewable energy highlights its potential to lead the world. Strategic investments in infrastructure, energy, and R&D will be crucial in sustaining this momentum and positioning India as a preferred global manufacturing destination.

Future outlook and recommendations

As global manufacturing undergoes a paradigm shift, India is uniquely positioned to capitalise on emerging opportunities. By aligning with global trends and focusing on quality, Indian manufacturers can establish themselves as reliable partners on the world stage.

Policy reforms must continue to support this growth trajectory. Simplifying regulatory processes, promoting ease of doing business, and incentivising R&D investments are critical for fostering a robust manufacturing ecosystem. Additionally, enhancing infrastructure and ensuring reliable energy sources will address key bottlenecks.

India’s journey towards becoming a global manufacturing hub requires collective efforts from all stakeholders. By embracing sustainability, innovation, and inclusivity, the Indian manufacturing sector can achieve unparalleled growth and redefine its global footprint.

Summary

The ‘Make in India’ initiative embodies the vision of transforming India into a global manufacturing hub. By addressing challenges and capitalising on opportunities, India is poised to redefine its manufacturing narrative and emerge as a key player on the world stage. Companies are leveraging strategic investments, eco care manufacturing practices, advanced technologies, and skilled manpower to drive growth.

About the author:

Kamlesh Panchal is a leader with three decades of experience in air and gas compressor technology. He has expertise in high-specification, short delivery, complex projects around turnkey solutions with standard high volume compressors production. He has played a key role in driving growth for Atlas Copco Gas and Process Operations in India, overseeing large machinery deliveries to process industries and international clients, as well as establishing a new packaging facility. Currently, Panchal serves as General Manager at Atlas Copco India Pvt Ltd, Dapodi, Pune leading a diverse product portfolio for both local and global customers. He is also leading a landmark greenfield project to establish a compressor manufacturing facility in Talegaon.

Photo Credit: Freepik

Related Stories

Indian manufacturing sector has a very promising outlook: Amitabh Kant

In this interview with Rakesh Rao, Amitabh Kant, India's G20 Sherpa and former CEO of NITI Aayog, explores the country’s transformative journey in the last few years and potential of the Indian ma..

Read more

Knowell can support India’s next wave of industrial growth: Jatin Shah

In this interview, Jatin Shah, MD and CEO, Knowell International Pvt Ltd, highlights the importance of bearings in propelling the growth of the Indian manufacturing sector.

Read more

India’s engineering sector has grown into a dynamic ecosystem: Amit Sharma

In this exclusive interview with Rakesh Rao, Amit Sharma, MD & CEO, Tata Consulting Engineers Ltd, highlights the transformation taking place in India’s engineering sector and the company's future..

Read moreRelated Products

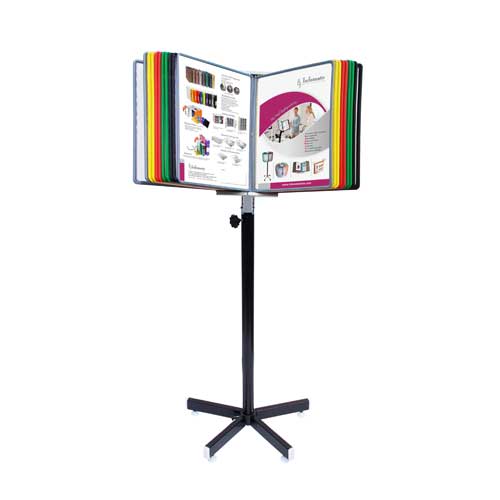

Dna of All Information

Roto Leaner Technology Pvt Ltd manufactures a complete range of display solutions.

Standard Series Stations and Enclosures

Esbee

Industrial Combines/Esbee Electrotech LLP offers standard series stations and

enclosures.

Fire Alarm

Safe Zone is prominent traders and suppliers of the industry, offering a wide range of wireless fire alarm.

Read more