Schedule a Call Back

Igus expands E4.1 e-chain system by adding roller links

Technical Articles

Technical Articles- Jan 01,18

Related Stories

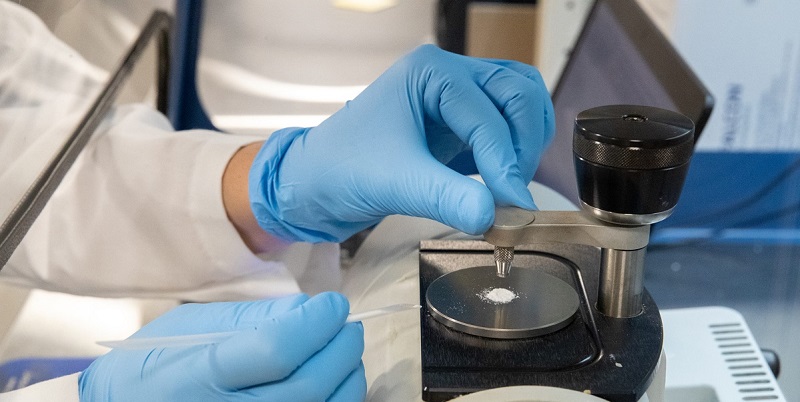

DCGI introduces guidelines for product traceability in pharma supply chain

The introduction of these guidelines is particularly timely, as the Indian pharmaceutical industry has come under scrutiny following reports linking spurious cough syrups from India to children's de..

Read more

Go Zero Lubrication: Igus’ clean revolution with lubrication-free plastics

With $990 billion spent on lubrication per year worldwide, igus, at Hannover Messe 2024, demonstrated who can do without lubricants immediately and the role AI plays.

Read more

Why are robot makers opting for integrated control?

Automation suppliers have been offering solutions for machine-integrated robot control for many years. But, with the strong increase in the adoption of robots since 2021, demand for integrated contr..

Read moreRelated Products

Automation Studio Copilot

B&R Industrial Automation offers a wide range of automation studio copilot.

Industrial Desalination System

Shakunth Aqua Products offers a wide range of industrial desalination system. Read more

Industrial Castors & Wheels

H M Gulamali offers a wide range of castors and wheels manufactured by Blickle, Germany. Read more