Schedule a Call Back

8.56 bn cubic meters of wastewater needs to be treated yearly to meet UN goals, says ABB report

Industry News

Industry News- Mar 23,23

Related Stories

Automation Studio Code offers a new automation engineering experience

This development plug-in is perfectly integrated into Automation Studio 6 and makes working on a project with two tools possible without any migration required ¬¬¬¬, fully compatible and flexibl..

Read more

We are shaping a low-carbon future through our platforms: Neeraj Kulkarni

For new and emerging industries, particularly those built around green hydrogen, e-mobility, or large-scale data centers, maintaining a stable and resilient power supply is crucial, says Neeraj Kulk..

Read more

Abb India’s Nelamangala campus achieves Mission to Zero™ status

ABB Nelamangala location, which delivers electrification motion, robotic and automation solutions for a variety of industries, is ABB’s second Mission to Zero™ site in India. Mission to Zero™ ..

Read moreRelated Products

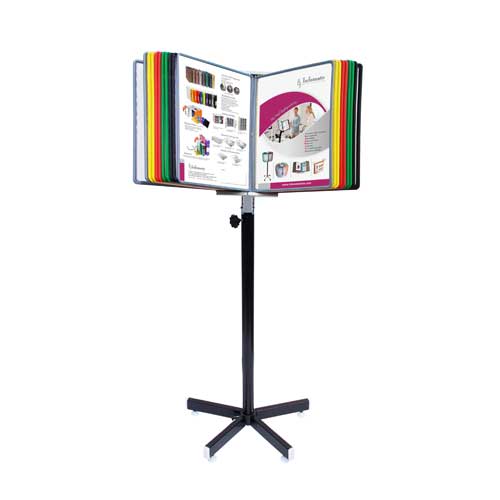

Dna of All Information

Roto Leaner Technology Pvt Ltd manufactures a complete range of display solutions.

Standard Series Stations and Enclosures

Esbee

Industrial Combines/Esbee Electrotech LLP offers standard series stations and

enclosures.

Fire Alarm

Safe Zone is prominent traders and suppliers of the industry, offering a wide range of wireless fire alarm.

Read more