Schedule a Call Back

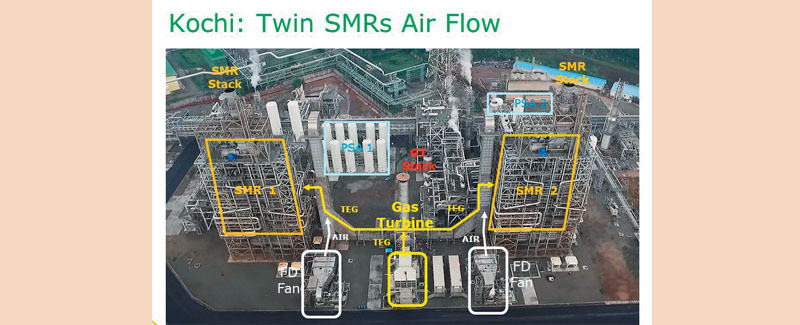

Air Products’ Kochi refinery: A world-class industrial gas complex

Communication Feature

Communication Feature- Nov 15,19

Related Stories

Sundararaman Ganapathiraman's EmBossed Imprints: A book for conscious leaders

"EmBossed Imprints: A-Z of Leadership Traits", Sundararaman Ganapathiraman's second book, serves as a ready reckoner for professionals who aspire to lead not just with competence, but with character..

Read more

Transforming Industrial Production: Khushboo Doshi

The industry is seeing a significant shift toward circular economy principles, with manufacturers developing technologies that support the processing of recycled materials and the production of sust..

Read more

Elektrolites will be unveiling smart grid solutions in 2025: Anil Saboo

In this interaction, Anil Saboo, CMD, Elektrolites Power Pvt Ltd, explains the trends in the industry and the company's plans for ELECRAMA 2025.

Read moreRelated Products

Air Generators

Enersys offers a wide range of hot air generators. Read more

Gas Roaster

Fans Bro Erectors offers roaster machine with LPG/CNG gas heating arrangements. Read more

Gas Purification System

PCI Analytics offers a wide range of GC gas purification system. Read more