Schedule a Call Back

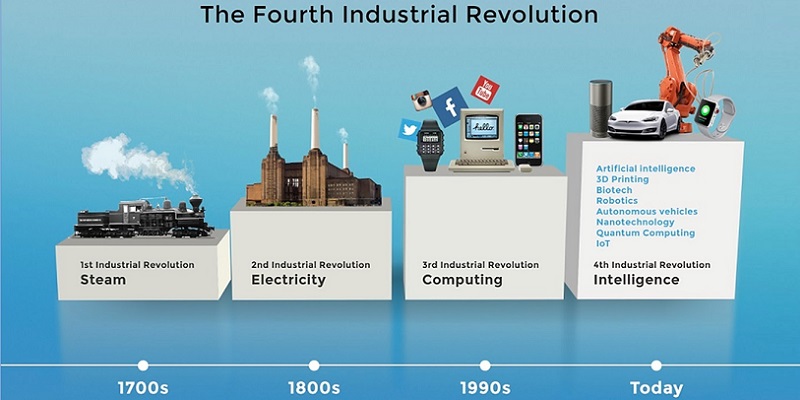

Indian manufacturing industry roaring ahead

Technical Articles

Technical Articles- Apr 26,18

- Bank recapitalisation

- The steel policy

- Re-establishment of coal linkages

- Establishment of industrial corridors

- Formation of the national grid for energy distribution

- Reduction of income tax rate for MSME companies

Related Stories

Surface Modification Technologies aims for global expansion: Dr Umesh Mhatre

In this interview, Dr Umesh Mhatre, MD, Surface Modification Technologies Pvt Ltd, highlights his company’s contribution to the growth of manufacturing sector and plans for IMTEX 2025 exhibition.

Read more

A new future: The advent of a ‘provice’

This is a new era, where each product is a combination of product and service, and hence, there is an urgent need of a new term for this new creature. My choice is ‘provice’, till a better name ..

Read more

Related Products

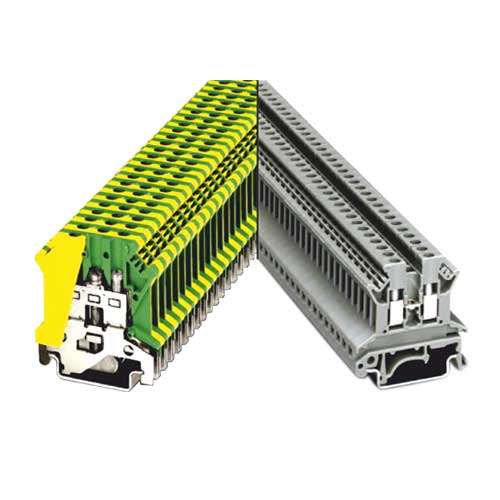

78 Series Din Rail Terminal Blocks

Werner Electric Private Limited offers a wide range of 78 series din rail terminal blocks.

Mig Welding Torches

ATE Welding Engineering Robotics & Automation offers MIG welding torches. Read more

Puma Lift Electric Stacker

Puma Lift Trucks Pvt Ltd offers a wide range of puma lift

electric stacker.