Schedule a Call Back

Excavators to march ahead on infrastructure demand

Articles

Articles- Jul 01,19

Related Stories

CII, KPMG and Synopsys Unveil India’s First Engineering Hardware Startup Report

The report provides a comprehensive overview of India’s evolving hardware innovation landscape and its challenges, along with actionable recommendations for stakeholders across the ecosystem.

Read more

Mehru Secures Rs 260 Mn Order for High-Voltage Oil-Cooled Current Transformers

MEHRU has secured a major order valued at approximately Rs 260 million, the largest single order for the supply of 400kV and 220kV oil-cooled current transformers.

Read more

Elastocon: Engineering Uninterrupted Conveying

Kamlesh Jain, Managing Director of Elastocon, presents the five year vision of the company.

Read moreRelated Products

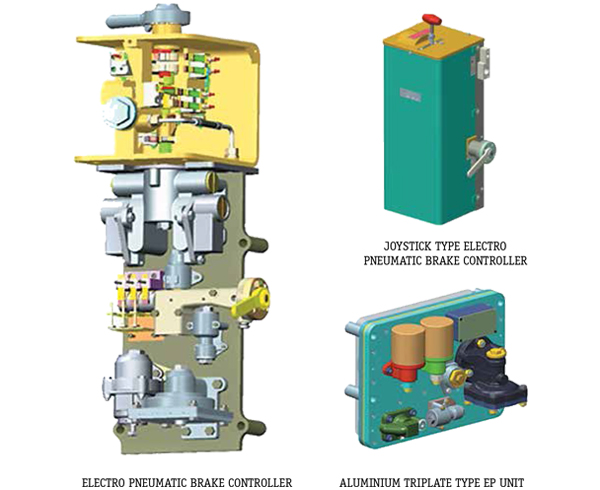

Electro - Pneumatic Brake System for Emu

Escorts Kubota Limited offers a wide range of electro - pneumatic brake system for EMU.

Indef Powered Crane Kit

Hercules Hoists Ltd offers a wide range of Indef powered crane kit.

Jib Crane

DC Hoist & Instruments Pvt Ltd offers a wide range of Jib crane.