Schedule a Call Back

Best practices to ensure safer work at heights across industries

Articles

Articles- Dec 02,25

- Plan to complete as much work as feasible, from ground level.

- Prioritise using scaffolding instead of ladders for working at heights.

- Ensure that workers can access and depart their work areas at height securely.

- Confirm the equipment is appropriate, sturdy, capable of supporting the workload, regularly checked, and well-maintained.

- Take preventive measures when operating on or near fragile surfaces.

- Supply protection against falling objects.

- Think about and have emergency evacuation and rescue procedures in place.

- Don’t allow employees exceed the load carrying capacity of any access equipment. Consider the worker’s weight along with the equipment or materials being carried while designing/ choosing the access equipment. Insert a pictogram or label on the ladder depicting information about safe usage.

- Prevent employees from overreaching on ladders or stepladders.

- Place caution signs about fragile surfaces so that employees don’t rest a ladder against those surfaces, such as glazing or plastic gutters.

- Refrain workers from using ladders or stepladders for physically demanding or heavy tasks. Reserve them for light work of short duration, for example, a maximum of 30 minutes.

- Never allow someone who isn’t competent (lacks the necessary skills, knowledge, and experience) to work at height.

Related Stories

Five Trends That Will Define the Evolution of Quick Commerce in 2026

Multi-city footprints expanded, service levels tightened, and fulfilment networks scaled from small clusters to nationwide grids.

Read more

Knauf India doubles capacity with new metal line at Khushkhera plant

The increased production capacity is expected to improve the company’s ability to meet rising domestic demand and support a wider portfolio of drywall and ceiling solutions.

Read more

Manufacturing to Drive 46% of Industrial Leasing by 2027: JLL

JLL forecasts manufacturing leasing to reach 34 mn sq ft across top cities.

Read moreRelated Products

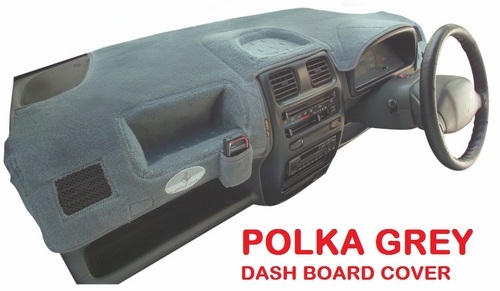

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.