Schedule a Call Back

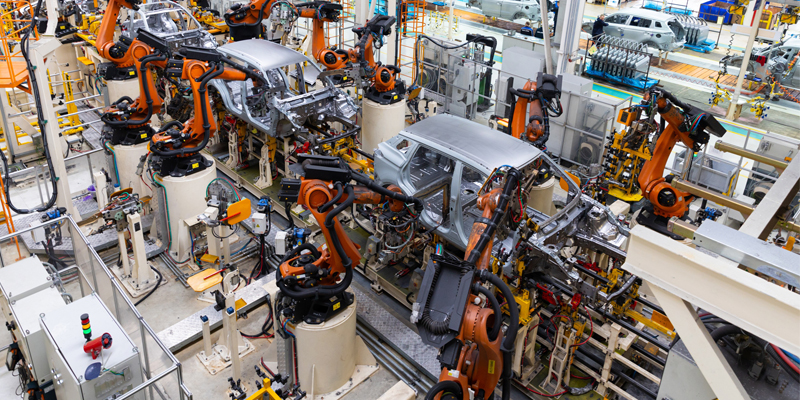

Smart spindle: The future of robot deburring

Communication Feature

Communication Feature- Dec 01,18

- Burr size changes

- Work piece size variations

- Correct lubrication

- Tool in contact with material

- Situation and position control of work piece

- Shattering during process

- Deviation of working air pressure

- Monitoring of insert tool wear and breakage

- Initiate tool change

- Service warning

Related Stories

Smart Factories in India: Reality or Distant Dream?

As India moves toward its goal of becoming a $7 trillion economy by 2030, embracing smart manufacturing technologies will be crucial for achieving this ambitious target, writes Rakesh Rao. But, is t..

Read more

UNITED GRINDING and GF Machining merge to form UNITED MACHINING SOLUTIONS

The new entity will be one of the world's largest machine tool manufacturers with $ 1.5 billion in sales.

Read more

DiFACTO Robotics acquires RoboFinish Division from Grind Master

RoboFinish portfolio, which includes robotic grinding, finishing, deburring, and machining technologies, presents significant synergies with DiFACTO’s existing offerings, strengthening its positio..

Read moreRelated Products

Ac Servo Motorum 3048tg With 8-station Tapping

Meiban Engineering Technologies Pvt Ltd offers a wide range of AC servo motorum 3048TG with 8-station tapping.

High Quality Thread Turning

Vardex Tooling Private Limited offers a wide range of high quality thread turning.

Practica Cnc Shear - Oscillating Knife Beam Cnc Shear

Deratech Machines India Pvt Ltd offers Practica CNC hydraulic shears with oscillating knife beam are sound, heavily built machines. Read more