Schedule a Call Back

Hydrogen Pipelines: Key to India’s Clean Energy Future

Articles

Articles- Jul 28,25

Related Stories

R&D is a key enabler of the Make-in-India initiative: Rajendra Petkar

In this interview with Rakesh Rao, Rajendra Petkar, President & CTO, Tata Motors, explains why R&D is essential for India’s transition to a developed, innovation-led economy.

Read more

How Solar and Battery Storage Synergy can Meet Peak Energy Demand in India?

While solar PV systems offer clean energy during daylight hours, they alone are insufficient to meet peak energy demand in the country, especially during summer. In this article, Minakshi Baranwal, ..

Read more

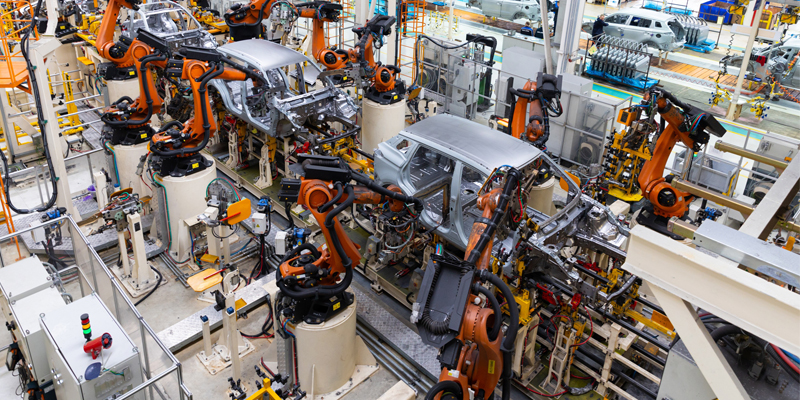

Atmanirbhar by Design: Route to India’s Manufacturing Renaissance

For the success of Viksit Bharat 2047, the capital-goods sector needs to grow by tenfold from present Rs 5.5 trillion to Rs 60 trillion within two decades. Yogesh Pandit, Director of Product Acceler..

Read moreRelated Products

Programmable Controllers - Pcd-33a Series

Pro-Med Instruments (P) Ltd offers a wide range of programmable controllers - PCD-33A Series.

Gasket Graphite Powder

Arihant Packing & Gasket Company offers a wide range of gasket graphite powder.

Asahi Kasei expands 3D printing filament sales in North America

Asahi Kasei, a leading resin and compounding technology provider, has initiated the sales of 3D printing (3DP) filaments in North America through Asahi Kasei Plastics North America (APNA). The soft la Read more