Schedule a Call Back

Automation ensures ‘Right-First-Time’ production output: Sanjeev Dharwadkar

Interviews

Interviews- Oct 28,24

Related Stories

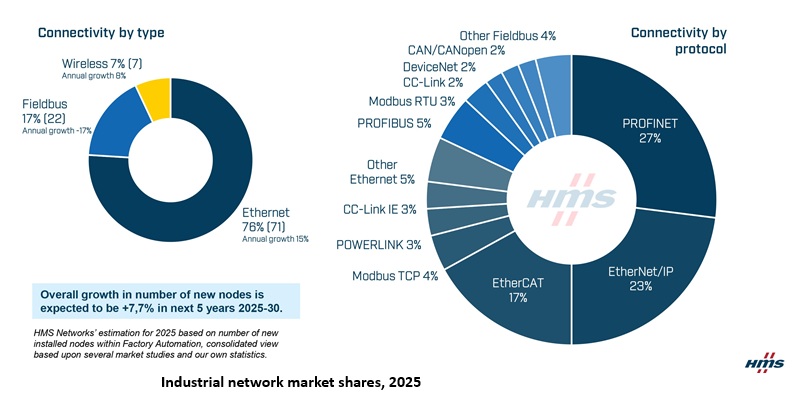

Industrial Ethernet now powers 76% of factory automation nodes: HMS Networks

HMS Networks’ 2025 report shows Industrial Ethernet now powers 76 per cent of new factory automation nodes, as fieldbus tech declines. Despite a short-term slowdown, long-term market growth is for..

Read more

DiFACTO Robotics acquires RoboFinish Division from Grind Master

RoboFinish portfolio, which includes robotic grinding, finishing, deburring, and machining technologies, presents significant synergies with DiFACTO’s existing offerings, strengthening its positio..

Read more

Phoenix Contact’s Trio Power: Reliable Power Supply for Material Handling

Phoenix Contact’s Trio Power: Reliable Power Supply for Material Handling

Read moreRelated Products

Programmable Controllers - Pcd-33a Series

Pro-Med Instruments (P) Ltd offers a wide range of programmable controllers - PCD-33A Series.

Gasket Graphite Powder

Arihant Packing & Gasket Company offers a wide range of gasket graphite powder.

Asahi Kasei expands 3D printing filament sales in North America

Asahi Kasei, a leading resin and compounding technology provider, has initiated the sales of 3D printing (3DP) filaments in North America through Asahi Kasei Plastics North America (APNA). The soft la Read more