Schedule a Call Back

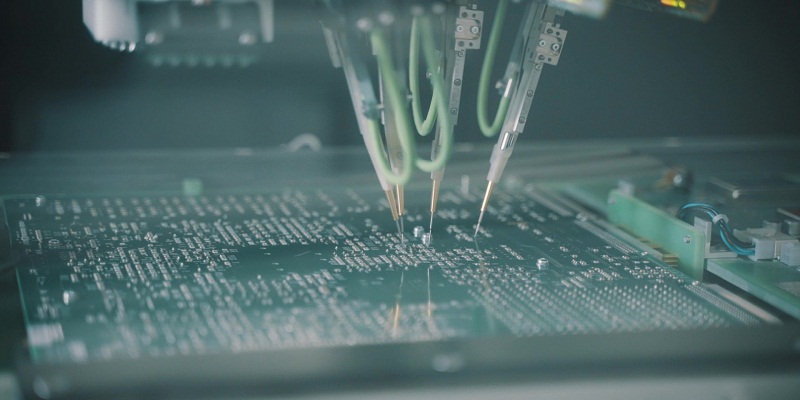

Why must PCB manufacturers conduct environmental tests on products?

Articles

Articles- Oct 19,22

Related Stories

In electronics, deeper localisation is the key for value creation: Mukesh Vasani

In this interview, Mukesh Vasani, Chairman & MD, Aimtron Electronics, emphasises that long-term consistency, capital support and ecosystem development are essential to building a resilient, export-d..

Read more

We are targeting 55 per cent growth: Rakshit Mathur

MIC Electronics has been in business since 1988. In this interview, Rakshit Mathur, CEO, MIC Electronics, outlines its railway focus, diversification plans, export revival and growth strategy.

Read more

Physical AI is accelerating rapidly across sectors: Krishna Rangasayee

SiMa.ai delivers a purpose-built, software-centric platform for physical AI. In this interview, Krishna Rangasayee, CEO and Founder, SiMa.ai outlines its vision, India partnerships, and mission-crit..

Read moreRelated Products

Integrated Electric Gripper S Series

IBK Engineers Pvt Ltd offers a wide range of integrated electric gripper S series.

Geared Electric Motors

Delco Fans Pvt Ltd offers single phase capacitor run and three

phase geared Instrument motors, totally enclosed face/foot mounted.

“Kusam-Keco” Partial Discharge Acoustic Imager - Model - Km-pdai

‘Kusam-Meco’ has introduced a new “Partial Discharge Acoustic Imager Model KM-PDAI.