Schedule a Call Back

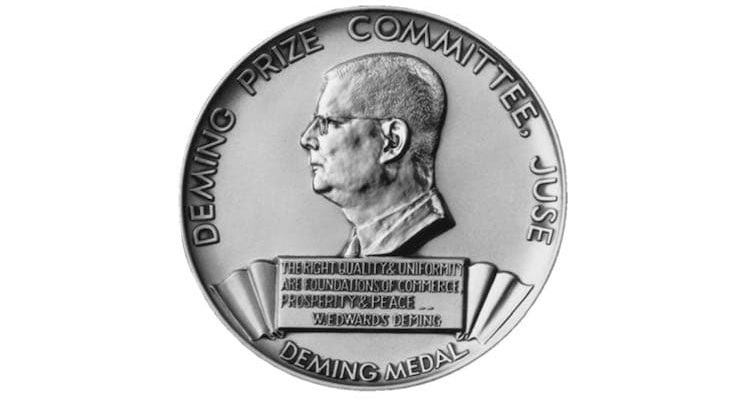

The contribution of the Deming Awards and Prizes to Indian industry

Articles

Articles- Nov 11,22

Related Stories

Pralhad Joshi Highlights India’s Economic Growth & BIS’s Role in Global Standards

Government harmonizing QCOs for certification to curb substandard goods. Pralhad Joshi highlights India’s growth, BIS's role in standards, and key initiatives.

Read more

India’s petrochemical economy: Opportunities for manufacturing industry growth

With supportive government policies and robust market demand, the Indian petrochemical industry has the potential to emerge as a pillar of industrial self-reliance, write R Jayaraman and T C R Amon.

Read moreAre IIOT sales strategies holding up adoption of Industry 4.0 in manufacturing?

As Industry 4.0 matures, Industrial IOT (IIOT) platforms will be the backbone of digital transformation. But adoption depends as much on how they are sold as on what they deliver, write R Jayaraman ..

Read moreRelated Products

Automotive Oil Pump

Kalpak Auto Pvt Ltd offers a wide range of

automotive oil pump.

Tata Motors unveils facilities for development of Hydrogen propulsion tech

Tata Motors, India?s largest automobile company, unveiled two state-of-the-art & new-age R&D facilities for meeting its mission of offering sustainable mobility solutions. The unveilings constitute of Read more

Tata Motors plans petrol powertrain for Harrier and Safari SUVs

Tata Motors is in the process of developing a new petrol powertrain for its premium sports utility vehicles, the Harrier and Safari, as confirmed by a senior company official. Currently, these models Read more