Schedule a Call Back

The 8 best ways to improve construction site productivity

Articles

Articles- Apr 15,22

Related Stories

How is AI shaping the future of cement milling?

AI is transforming cement milling by enabling dynamic, data-driven control that improves energy efficiency, stabilises throughput and enhances asset reliability. By leveraging real-time data, predic..

Read more

Tata Motors Unveils CV, Electric, CNG Tippers at EXCON 2025

Tata Motors showcased heavy-duty trucks, electric and CNG tippers at EXCON 2025, unveiling future-ready solutions to boost productivity, efficiency and sustainability for India’s construction sect..

Read more

EXCON 2025 Sets New Benchmarks for India’s Construction Equipment Sector

EXCON 2025 set new benchmarks in scale and participation, reinforcing India’s position as the world’s third-largest construction equipment market and showcasing the sector’s readiness for sust..

Read moreRelated Products

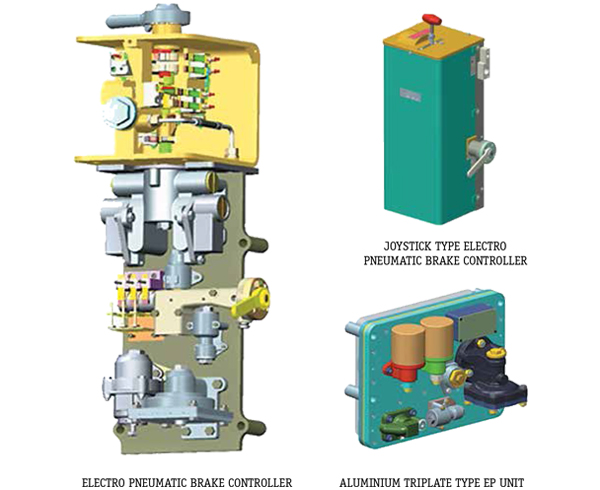

Electro - Pneumatic Brake System for Emu

Escorts Kubota Limited offers a wide range of electro - pneumatic brake system for EMU.

Indef Powered Crane Kit

Hercules Hoists Ltd offers a wide range of Indef powered crane kit.

Jib Crane

DC Hoist & Instruments Pvt Ltd offers a wide range of Jib crane.