Schedule a Call Back

Salvagnini showaces solutions at EuroBLECH 2024

Industry News

Industry News- Oct 16,24

Related Stories

EuroBLECH 2024 wraps up with encouraging results

With 38,946 trade visitors from 114 countries and 1.317 exhibitors on 160,000sqm gross space, the event reaffirmed its role as the world’s leading platform for innovation and business in this sect..

Read more

Salvagnini showaces solutions at EuroBLECH 2024

The Generation 4 lineup was engineered to eliminate low-value-added activities, reduce lead times, and optimise production flows, ultimately lowering product costs while enhancing business competiti..

Read more

ETA launches Dynaform 7.2: A sheet metal forming simulation software

Notable enhancements include improvements in Blank Size Engineering (BSE), Die Face Design (DFD), Formability Simulation (FS), and Tube Bending & Forming (TBF).

Read moreRelated Products

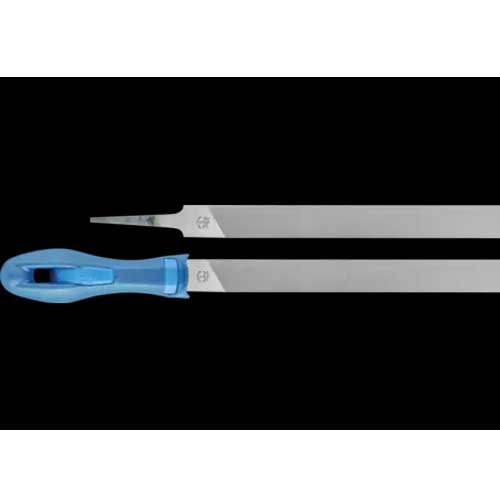

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.

Ss Hex Head Bolts

Trychem Metal And Alloys is offering SS hex head bolt.

Cutting Tools

Get Cutting Tools provides a wide range of CNC cutting tools