Schedule a Call Back

Role of cybersecurity in smart manufacturing

Articles

Articles- Nov 29,24

Related Stories

NBC Bearings and Ahamani EV Technology form JV for advanced drones in India

NBC Bearings partners Ahamani India to scale advanced drone solutions, strengthening Make in India and localisation efforts.

Read more

Budget Expectation: Why Materials, Data and Governance Will Shape Manufacturing

India’s manufacturing growth hinges on digitalisation, material self-reliance, and policy clarity to strengthen resilience and global competitiveness, says S Sunil Kumar, Country President, Henkel..

Read more

India–EU FTA sealed, offers preferential EU access to over 99% of Indian exports

The agreement is expected to be particularly transformative for labour-intensive sectors and MSMEs, with positive spillovers for employment generation among women, artisans, youth and professionals.

Read moreRelated Products

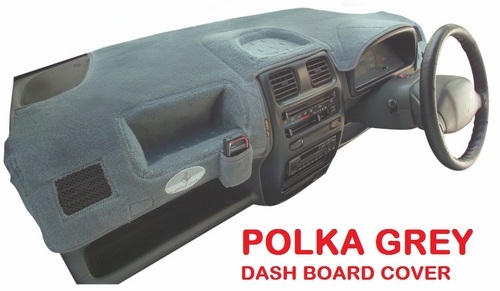

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.