Schedule a Call Back

Let’s seize the emerging growth opportunities

Articles

Articles- Feb 17,23

The Indian manufacturing industry is one of the key drivers of the country's economy, contributing around 17 per cent to its GDP. However, for the industry to reach its true potential, it must overcome several challenges and take advantage of new opportunities. In this article, we will explore the present status of the manufacturing industry, the key challenges it faces, and new opportunities for growth. We will also discuss the importance of advanced manufacturing technologies, skill development and training, and sustainability for the Indian manufacturing industry.

Present status

The present status of the Indian manufacturing industry is one of steady growth, with the sector expanding at a rate of around 5 per cent per year. However, this growth has been constrained by several challenges, including the ongoing Russia-Ukraine war, which has led to an increase in global uncertainty and a decrease in demand for goods. Additionally, there are concerns about the lack of adoption of the latest technologies in India, which makes it difficult for the country to compete with other nations like Taiwan, Korea and China.

Another challenge facing the Indian manufacturing industry is the lack of infrastructure, which can make it difficult for manufacturers to transport goods and components to and from their factories. There are also concerns about the competitiveness of Indian industries compared to other countries, which can make it difficult for Indian manufacturers to sell their products on the global market.

Despite these challenges, there are also new opportunities for the Indian manufacturing industry. For example, the China Plus One policy, which encourages companies to diversify their manufacturing locations, has created new export opportunities for Indian manufacturers. Additionally, the government's Production Linked Incentive (PLI) scheme and the Atmanirbhar Bharat initiative have also provided new opportunities for the industry.

To take advantage of these opportunities, advanced manufacturing technologies like robotics, Industry 4.0, additive manufacturing (3D printing), AI/ML, etc., must be adopted by the Indian manufacturing industry. These technologies will help increase India's competitiveness in the global market and make it easier for Indian manufacturers to produce goods at a lower cost.

In addition, skill development and training is crucial for the Indian manufacturing industry, especially as the dynamics of manufacturing are changing. With new technologies being adopted, it is important that workers are trained to use these technologies, so that they can be more productive and efficient. The Government of India has already initiated various schemes to develop the skill of the workers and make them industry ready.

The necessity of empowering small and medium-sized firms (SMEs) and start-ups is another crucial part of India's manufacturing sector. These businesses frequently serve as the manufacturing industry's growth catalysts; thus it is important to provide them with the assistance they need to expand their manufacturing operations. The Indian government has also launched a few initiatives for SMEs to support their growth and expansion by offering simple loans, banking, and financing plans to ease the business.

Finally, sustainability is also important for the Indian manufacturing industry. With new global and Indian regulations being introduced to address environmental and sustainability concerns, it is important that the industry adopts sustainable practices. Not only will this help to protect the environment, but it will also create new export opportunities for Indian manufacturers. The government of India is also taking several initiatives to promote sustainability in the manufacturing industry.

India aims at achieving $1 trillion Gross Value Added (GVA) from manufacturing in the next 5 years. It aims to increase the sector's contribution of GVA to over 20 per cent. An Empowered Group of Secretaries (EGoS) has been approved to make it easier for investors to invest in India and to accelerate growth in important economic areas. The Department for Promotion of Industry and Internal Trade (DPIIT) has proposed several ideas to make Indian manufacturing competitive on a global scale, taking a leaf out of the industrial success of nations like China, South Korea, and Vietnam. DPIIT has designated several areas, including land and power, for pressing reforms in its draught strategy paper on reforming industrial growth. The goal is to increase manufacturing's contribution to India's Gross Domestic Product (GDP) to 20 per cent by 2025. The strategy paper's key area is expanding manufacturing in the nation to reach the target of a $5 trillion economy.

Building capabilities

When it comes to other transportation infrastructure in India, the road and highway sector has historically gotten the most significant attention. With its rapid speed, road and highway development is even smashing records (38 km per day and laying of a 2.5 km road in just 24 hours). In 2022–2023, it is now intended to build 50 kilometres in a single day. From 91,287 km in 2014 to 1,41,000 km in 2021, the length of national roadways has also expanded dramatically. Under the ambitious Bharatmala scheme, the government intends to build 35 multi-modal logistics parks, 23 tunnels and bridges, 22 greenfield motorways, including the Delhi-Mumbai Expressway. The shipping industry was particularly heavily hit by the effects of COVID-19 as ports continued to be overcrowded worldwide with longer turnaround times, backlogs, and a shortage of trucks and containers. Global supply networks are erratic, as seen by the growing shipping delays and the escalating shipping costs for 20-foot dry containers ($800 pre-pandemic to $2250 post-pandemic).

The current capacity is not sufficient for the anticipated 2,500 MTPA increase in freight traffic in 2025. The Indian government declared in 2021 that it will enhance port infrastructure and allocate $82 billion for port projects. It has identified 92 minor ports for capacity augmentation, which will increase the current capacity by 712 MTPA. It is intended to build two new, large greenfield ports at Vadhavan in Maharashtra and at Paradip Outer Harbour in Odhisha.

The corporate tax rates for both new and existing manufacturing enterprises have already been rationalised by the central government. Additionally, the Manufacture and Other Operations in Warehouse Regulations (MOOWR) have been adopted to allow for the postponement of import customs duties, the waiver of interest on postponements, the elimination of the requirement for export obligations, and flexibility in location setup. Additionally, the international trade strategy provides financial relief to exporters in the form of tariff scripts on foreign transactions, which can be liquidated as a cash incentive. In order to create incentives for compensating for hidden tax costs in exports, the government recently updated the MEIS plan (Merchandise Exports from India Scheme) and replaced it with the new RODTEP scheme (Remission of Duties & Taxes on Export Products).

Boosting investment

The Department for Promotion of Industry and Internal Trade (DPIIT) estimates that in FY 2021–2022, India got a total inflow of $ 58.77 billion in foreign direct investment (FDI). The Ministry of Defense would receive Rs 525,166 crore ($ 67.66 billion) from the Union Budget 2022–23. The government set aside Rs 2,403 crore ($ 315 million) to promote the production of IT hardware. Around 80 per cent of all manufacturing expenses are spent on the production of electronics, vehicles, and solar panels, with the semiconductors/electronics value chain accounting for 50 per cent of all expenses in February 2022. Capacity utilisation in India's manufacturing sector was 72 per cent in the second quarter of FY22, according to a poll by the Federation of Indian Chambers of Commerce and Industry (FICCI), showing a considerable rebound in the industry.

With an estimated cost of Rs 10,683 crore ($ 1.45 billion), Prime Minister Mr Narendra Modi approved the production-linked incentive (PLI) plan in the textile industry in September 2021 for man-made fiber (MMF) garments, MMF fabrics, and 10 segments/products of technical textiles. To promote exports from the agriculture sector, the Ministry of the Food Processing Industry's "Operation Green" programme, which was previously only available for onions, potatoes, and tomatoes, has been expanded to include 22 perishable products. Infrastructure plans for horticultural products will be made easier as a result. The Defense Ministry announced a tender in July 2021 for the construction of six conventional submarines as part of Project-75 India at a cost of Rs 50,000 crore ($ 6.7 billion) to promote Make in India.

A programme called the Production-Linked Incentive (PLI) was started with an allocation of Rs 1.97 lakh crore ($ 27.02 billion) over the following five years to create global manufacturing champions in 13 sectors (starting FY22). The market for display panels in India is predicted to increase from $7 billion in 2021 to $15 billion in 2025. With the pandemic phasing out, the manufacturing sector's forecast appears to be on track.

It has been noted that manufacturing goods enable a country to export to 'unlimited' international demand. Additionally, this avoids the constraints of domestic demand, which is governed by domestic income and serves as a solid restraint on growth. Select industries will receive additional support in addition to initiatives to reduce the cost of production inputs. For instance, there would be a strong push for electric vehicles. To increase the use of electric vehicles (EVs) in the nation, policy measures would be implemented. The government may think about signing mining and free trade agreements with resource-rich nations in Africa (Congo, South Africa), Latin America (Bolivia, Argentina, Chile), and other regions to get vital minerals like lithium and cobalt and turn India into a major producer of EVs.

The PLI projects have 13 sectors covered as of November 2021, with a total budgeted spend of Rs 1970 billion ($ 26.48 billion). Depending on the industry, each PLI programme is valid for a duration of four to six years. These industries include the automotive, drone, electronics, IT hardware, pharmaceutical, medical, and specialty steel markets. The PLI for semiconductor production has even been set at Rs 760 billion ($ 9.71 billion), with the goal of making India one of the world's top producers of this crucial component. India will enter a new level thanks to the semiconductor industry, where the nation will be seen as a manufacturing hub on a worldwide scale.

Summing up

With the pandemic phasing out, the manufacturing sector's forecast appears to be on track. India's manufacturing industry has the potential to generate $1 trillion in revenue by 2025. The Government seeks to ensure the overall growth of the country by placing emphasis on the development of industrial corridors and smart cities.

In conclusion, the Indian manufacturing sector has the potential to be a significant global participant, but it will need to overcome several obstacles and seize fresh chances. The Indian manufacturing sector may become a center for global manufacturing by 2025 by implementing sophisticated manufacturing technology, making investments in skill development and training, empowering SMEs, and start-ups, and implementing sustainable practices. India's manufacturing sector will undoubtedly achieve the necessary degree of growth and competitiveness in the international market with the government's ongoing backing and the efforts of the industry participants.

About the author:

Hiren Pravin Shah is the Executive Director & CEO of RePlus Engitech, a part of LNJ Bhilwara Group. He has 23 years of professional experience in energy storage domain with global firms like Panasonic and Delta Electronics. He has an experience of setting up complete supply chain, operation, O&M, product development and services ecosystems for lithium ion projects.

Related Stories

Greenfuel Launches Ferrule-less Tube Line to Boost Make in India

Greenfuel Energy Solutions opens a new ferrule-less tube line in Manesar, enhancing local manufacturing, technology transfer, and alternate-fuel vehicle support.

Read more

3D Printing Strengthens the Foundations of Smart Manufacturing

The global 3D printing market was estimated at $30.55 billion in 2025 and is projected to reach $168.93 billion by 2033, growing at a compound annual growth rate of 23.9 per cent from 2026 to 2033.

Read more

India’s Top 100 Engineering Companies 2025 by Smart Manufacturing & Enterprises

FY25 unfolded against a challenging external setting. Despite the global headwinds, India posted real GDP growth of 6.5 per cent in FY2024–25. In this edition, Smart Manufacturing & Enterprises (S..

Read moreRelated Products

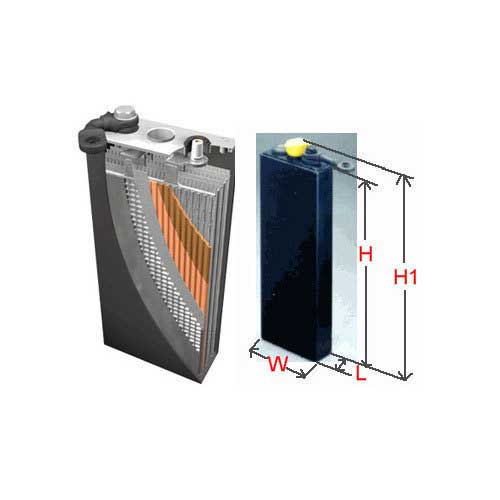

Forklift Battery

Aatous International is a manufacturer and solution provider of a wide range of forklift battery.

Kusam Meco -Wrist Type High Voltage Alarm

‘KUSAM-MECO’ has introduced a new wrist Type High Voltage Alarm Detector - Model KM-HVW-289 having a wide sensing range from 1kV-220 kV AC.

Servotech Power Systems files 2 patents for energy management technologies

Servotech Power Systems, a leading manufacturer of EV chargers and solar solutions, has announced that it has filed two patents for innovative energy management technologies in order to facilitate gri Read more