Schedule a Call Back

How is Industry 4.0 building on its predecessors?

Articles

Articles- Jul 11,23

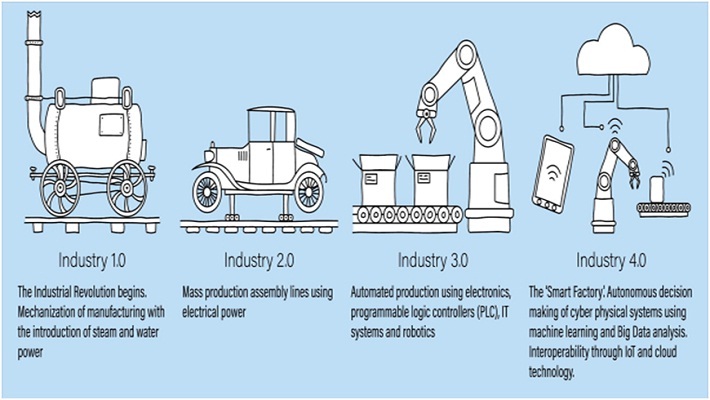

The industrial scenario is always in flux, peaking at some points in time, and building on the existing structure at others. The four peaks that have been observed, recorded and spoken about have been in the 1800’s, 1920, 1960 and 2000. The fifth revolution, Industry 5.0, is under incubation. According to the European Union, Industry 5.0 “provides a vision of industry that aims beyond efficiency and productivity as the sole goals, and reinforces the role and the contribution of industry to society and “It places the wellbeing of the worker at the centre of the production process and uses new technologies to provide prosperity beyond jobs and growth while respecting the production limits of the planet.” It complements the Industry 4.0 approach by “specifically putting research and innovation at the service of the transition to a sustainable, human-centric and resilient European industry”. One can summarise it by calling it Industry 4.0 with a human face.

Industry 4.0 originated in Germany, around the year 2000, although the term was popularised in 2015 by Klaus Schwab, the World Economic Forum founder and executive chairman. It has gained a lot of currency, in that, big data analytics, cloud computing, machine learning and robotics have all become ubiquitous in the manufacturing sector. eCommerce has epitomized and revolutionized its usage in the services sector. It may be a good time to take stock and understand the underlying forces in Industry 4.0 which are pushing the advancements from the previous stage of the industrial revolution.

In the first stage, craft production dominated, with many inventions leading the way to the enablement of the market-appearance of previously unknown products. Manufacturers could make the product, and it would sell itself. In the next stage, of mass production, mass markets, and the slow evolution of buyer’s markets in many parts of the world. This stage was remarkable for two peaking developments. One, the Total Quality Management (TQM). The other, Business Excellence, exemplified by the Malcolm Baldrige model for performance excellence followed by the BE model of the European Foundation for Quality Management.

These movements began in 1850 and 1987, respectively. These propelled the introduction of computerisation and automation which characterized the third stage of industrial revolution. This revolution, which began sometime in 1970/80, brought many changes in the producer – market dynamics. Increased productivity, through computerised MIS driven operations; speedy decision making through data capture and analysis; improved communications through LAN/WAN based connected systems; spread of IT systems for efficient operations; evolution of the ‘supply chain’ related concepts, like, value chain optimisation through lean management, balanced score cards led strategically aware corporations, emergence of a large IT savvy workforce; and a new industrial complex with ‘profit at any cost’ attitude.

In this milieu, came the telecom revolution. Telecom plus sensors plus electronics devices kicked off the Industry 4.0. So, how has Industry 4.0 changed the global business scenario? Let’s see the Table 1 for the main threads:

Table 1 only gives a glimpse of the changes that have happened in the Industry 4.0 era. There are many areas which have yet to reach maturity. For example, in operations, what is expected is ML facilitated, algorithms embedded, fully interconnected manufacturing, with cloud computing being the centrepiece. The Figure 1 shows a configuration of Industry 4.0 operations.

What is shown in Figure 1 should be replicated in all the value centres in the company. The value centres are as defined in the Porters Value Chai diagram. Then, the replication has to be done in all the stakeholders in the total value chain – which includes suppliers, vendors, warehousing, distributors, retailers, transporters, etc. This is the ‘ultimate reality’ of Industry 4.0 in manufacturing. This configuration will increase efficiencies across the board, and eliminate waste, something which is central to the concept of ‘sustainability’, as defined in the 17 SDG’s of the UN. This is shown in Figure 2. In the Figure 2, OS refers to the Operations Strategy of a manufacturing company.

Ultimately, Industry 4.0 will lead to sustainability, through the use of IOT, ML and other tools. This would have been impossible in Industry 3.0. Summarising, the key build-ups in Industry 4.0 over Industry 3.0 are connectivity, IOT, ML, AI, 3D Printing, Block Chain accounting (this is still in its evolutionary stage, not yet matured), which all will propel the industrial scenario towards prosperity through sustainability.

About the author:

R Jayaraman is the Head, Capstone Projects, at Bhavan's S P Jain Institute of Management & Research (SPJIMR). He has worked in several capacities, including Tata Steel, for over 30 years. He has authored over 60 papers in academic and techno economic journals in India and abroad. Jayaraman is a qualified and trained Malcolm Baldrige and EFQM Business Model Lead Assessor.

Related Stories

Mahindra Expands Advanced R&D and Testing Facilities at Chennai MRV

Mahindra & Mahindra invests Rs 1,960 million to expand its Advanced R&D and testing facilities at Mahindra Research Valley, creating 2,000 new jobs and reinforcing Chennai as an innovation hub.

Read more

MIC Electronics Secures Rs 44.5 million Eastern Railway Orders

MIC Electronics Limited has received Rs 44.5 million LoAs from Eastern Railway, Howrah Division, for advanced Passenger Information and Communication Systems projects.

Read more

Honeywell Launches Hybrid Heating to Cut Industrial Energy Costs and Emissions

Honeywell’s Hybrid Heating Solution enables manufacturers to switch between gas and electric heat in real time, helping optimise energy costs, cut emissions and support the energy transition.

Read moreRelated Products

Fanless Industrial Pc for Smart Manufacturing

CONTEC Launches BX-M4600 Series - Fanless Industrial PC for Smart Manufacturing.