Schedule a Call Back

Hannover Messe 2024: Powering Sustainable Manufacturing

Articles

Articles- May 27,24

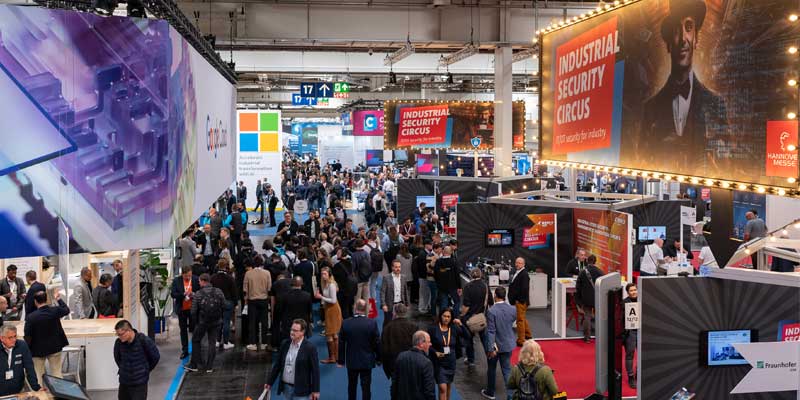

Hannover Messe 2024 once again demonstrated its ability to bring together the world’s best technology innovations, business partners and policy-makers on one platform to drive the global agenda of sustainable manufacturing. More than 130,000 visitors from 150 countries witnessed the innovative, futuristic solutions of 4,000 exhibitors and 300 start-ups from all over the world. Over 40 per cent of visitors came from abroad. Apart from the host nation of Germany, the top visitor nations were China, the Netherlands, South Korea, the US and Japan.

Participants were able to know how to profitably take advantage of automation, additive manufacturing, artificial intelligence, hydrogen and many other high-tech solutions in their factories, thus making them fit for the future. "It has been a future-oriented technology trade fair, since the innovations that drive industrial competitiveness and sustainability were on display here," remarked Dr Jochen Köckler, Chairman of the Managing Board, Deutsche Messe AG, during at the closing press conference for Hannover Messe 2024.

Like every year, Smart Manufacturing & Enterprises (SME) witnessed some of these impressively innovations first-hand and spoke to a few of them to know how they are gearing up to tap the mega trends of electrification, digitalization and automation.

Ultimaker eyes India with industrial grade 3D printer

Chevy Kok, VP APAC at Ultimaker

Ultimaker, the Netherlands-based 3D printing leader, created waves in the manufacturing industry with the launch of its industrial-grade 3D printing machine, the UltiMaker Factor 4. “Ultimaker Factor 4 is an end-to-end 3D printing solution for light industrial applications. Its capabilities extend beyond traditional manufacturing. Factor 4 boasts impressive features and can be used for applications like small-batch shoe production to large parts manufacturing with high efficiency and reliability,” said Chevy Kok, VP Asia Pacific (APAC) at Ultimaker.

Ultimaker focuses on empowering companies to adopt local, on-demand parts production using 3D printers. This approach optimises supply chains by eliminating the need for outsourcing and shipping finished goods. “Compared to traditional methods, 3D printing offers substantial cost savings. For instance, a €1500 application purchased off the shelf can be produced at a significantly lower cost using a 3D printer. Additionally, 3D printing drastically reduces lead times, enabling part creation within a day and a half compared to weeks or months with outsourcing. While currently manufactured in the Netherlands, Ultimaker Factor 4 machines are shipped across Asia. This centralised production ensures quality standards while optimised costs allow us to cater to the European, US, and Asian markets,” he stated.

Ultimaker goes beyond just hardware, it offers a comprehensive ecosystem encompassing materials, software, and bespoke services to cater to the diverse needs of manufacturers. While automotive is a strong application area for 3D printing in China and parts of India, the Indian market primarily utilises the technology for manufacturing jigs and fixtures to streamline assembly processes. This highlights the need for a tailored approach to drive 3D printing adoption in different regions. Chevy Kok explained, “In India, currently we sell our machines through the Mumbai-based Imaginarium, which is a pioneer in 3D printing in the country. We have been working with them for the last couple of years to introduce the technology to the India market. The collaboration, which started in 2022, is going strong. India's booming economy and manufacturing sector present a significant growth opportunity for Ultimaker. The company is optimistic about the market response, considering the potential for cost and time savings through 3D printing.”

Speaking about the potential of the new 3D printer in India, he said, “The Ultimaker Factor 4, with its modularity and competitive price point, holds immense potential for various applications in the Indian market. While commercially launched, the machine awaits shipment, and its arrival is sure to create a stir in the Indian manufacturing landscape.”

Uttar Pradesh uses HM2024 to draw global investors

Abhishek Prakash, Secretary IIDD & CEO Invest UP, Government of Uttar Pradesh

Uttar Pradesh (UP), which had a big booth at Hannover Messe 2024 (HM2024), used the platform to promote the state as a premier investment destination for global firms. “Under the visionary leadership of Honorable Prime Minister Narendra Modi and Chief Minister Yogi Adityanath, Uttar Pradesh (UP) has undergone a remarkable transformation in recent years, emerging as a prime destination for investment and economic growth. At Hannover Messe, we are focusing on key sectors like manufacturing, automobile, electric vehicles, battery manufacturing, tech-based, AI and robotics to name a few. We managed to sign four MoUs on the first day of HM2024 attracting investment from the motor sector of almost $ 13 million. Companies, who are looking for better investment opportunities or expansion, are approaching us as they see the potential in UP,” stated Abhishek Prakash, Secretary IIDD & CEO Invest UP, Government of Uttar Pradesh.

A key factor contributing to UP's attractiveness for investment is its robust law enforcement, ensuring a safe and secure environment for businesses to thrive. Moreover, the state boasts a stable policy framework, with over 25 sectorial policies and industrial policies offering incentives aimed at fostering growth across various industries. He added, “Notably, UP stands out as the only state in the country with a dedicated policy to attract Foreign Direct Investment (FDI), extending benefits to global Fortune 500 companies. The policy offers upfront land subsidies ranging from 25 per cent to 80 per cent, in addition to capital subsidies, making it highly lucrative for investors.”

Facilitating ease of doing business, UP has implemented a streamlined governance system through initiatives like Nivesh Mitra and Nivesh Sarathi websites, serving as the largest single-window platforms for investment. They have over 1.3 million applications processed.

Abhishek Prakash commented, “Under the dynamic leadership of Chief Minister Yogi Adityanath, UP has successfully hosted prestigious events like the Global Investor Summit in February, 2023, where MoUs worth ?33,000 billion were signed, showcasing the state's immense investment potential. Additionally, initiatives like participation in the Hannover Messe 2024 and groundbreaking ceremonies for over 14,400 projects further highlight UP's commitment to industrial growth and infrastructure development.”

Furthermore, UP has strategically established defense corridors to attract investors in the defense sector, with nodes in Lucknow and Kanpur witnessing notable production ventures by industry giants like Reliance and Adani. In addition to large enterprises, UP offers attractive incentives for Small and Medium Enterprises (SMEs), including 20-25 per cent capital subsidies, concessional land rates, and stamp duty exemptions, further fostering an environment for entrepreneurship and economic growth.

“UP's proactive approach to investment promotion, coupled with its robust policy framework and governance reforms, positions the state as a premier destination for investors seeking lucrative opportunities in India's rapidly growing economy,” he said.

EEPC sees global gain for India’s engineering sector

Mukesh Gulab Samtani, Sr Assistant Director, EEPC India

With global companies looking for an alternate sourcing destination (due to their China Plus One policy), India is in a good position to increase its share in the global trade as it offers dual advantage – a big & growing domestic market and a platform to exports. “Because of the China Plus One policy, India stands to gain significantly as global attention shifts towards diversifying supply chains. With India's emergence as a preferred destination, there's a surge of interest in Indian products and manufacturing capabilities. Prime Minister Narenda Modi's ‘Make in India’ initiative has further boosted this perception, positioning India as a viable alternative for international businesses seeking to ease risks associated with over-dependence on China,” observed Mukesh Gulab Samtani, Sr Assistant Director, EEPC India.

EEPC India, established by the Ministry of Commerce in 1955 to promote Indian exports, has evolved its mission to foster trade beyond traditional export-import activities. Now, it actively cultivates overseas partnerships and participates in prestigious exhibitions worldwide, with substantial support from the Ministry of Commerce.

SMEs benefit greatly, receiving up to 40 per cent cost coverage for exhibition space, airfare reimbursement, and sometimes even accommodation assistance. Additionally, EEPC India hosts the Indian Engineering Exhibition (INDEE), an impactful platform showcasing Indian engineering prowess to global buyers, reversing the exhibition model to attract international visitors to India.

Samtani added, “The current global environment is not favourable. Most of the countries are under recession right now. India is booming, but the countries elsewhere are in a really bad state with all the wars and recessions taking place. The plan forward that we fight it out and see how we can move forward.”

Karkhana.io digitalising contract manufacturing sector

Karthik MC, Chief Revenue Officer, Karkhana.io

Karkhana.io, an innovative digital platform, is reshaping India's sourcing and contract manufacturing sector. Boasting a network spanning over 500 suppliers nationwide, Karkhana.io is dedicated to enhancing productivity and optimising capacity utilisation within India's vibrant supply ecosystem.

Founded by Sonam Motwani from IIT Bombay five years ago, Karkhana.io has evolved from offering prototyping services to providing comprehensive contract manufacturing solutions. Their current customer base exceeds 200; the platform has emerged as a pivotal player in India's manufacturing landscape. Karthik MC, Chief Revenue Officer, Karkhana.io, elaborated, “The platform caters to a diverse array of sectors, including electric vehicles (EVs), battery packs, medical devices, aerospace and drone components, IoT devices, and consumer electronics. These burgeoning industries present unique challenges, necessitating agile and dependable solutions. Over the past half-decade, Karkhana.io has meticulously assessed its suppliers' capabilities to ensure readiness to meet evolving manufacturing demands.”

Karkhana.io's suppliers primarily consist of MSMEs. These businesses vary in turnover, ranging from ? 70 million to ? 2-2.5 billion. Majorly, the suppliers are family-run enterprises.

“The adoption is quicker because you have lot of suppliers with underutilised capacity which is around 30-40 per cent. If one looks at most of the MSMEs their capacity utilisation is around 30-50 per cent and they also have the risk of overdependence on one or two customers. When any one of their customer’s account gets shut, they have no plan B. So these are the kind of suppliers we can support the most. Since we aggregate demand, so in some sense we are like a mutual fund, we de-risk. If one customer drops we still have a basket of customers to help their capacity utilisation. Depending on the industry the kind of project management skills required, may not be a competence they can completely build in. For example the aerospace industry, the documentation requirement is extremely stringent, they may not have the capability or the business may not have that kind of team. Since we aggregate for the industry, we can help them out with quality management, documentation, onboarding requirements and more. We are able to offer a complete solution,” explained Karthik.

At Hannover Messe 2024, Karkhana.io showcased India as a premier sourcing destination, offering reliability and efficiency in the process. Karthik informed, “The customer base primarily comprises medium-sized family-run businesses or well-funded startups. These companies because they have quick decision-making processes, and turnovers ranging from ?15-20 billion. Since their supply chains may not always adhere to the highest professional standards. Karkhana slips in to help out.”

Looking ahead, Karkhana.io aims to expand its global footprint, targeting 10 per cent of its turnover from exports by 2024. The company visions to establish a robust presence in the United States, leveraging existing positive sentiments towards Indian manufacturing as well as Germany for the strong industrial ecosystem present. As the platform continues to innovate and collaborate, it remains committed to driving growth and sustainability across India's manufacturing sector.

Elmex Electric targets international markets for growth

L-R: Bhairav Joshi, VP - International Business, and Vipul Ray, MD, of Elmex Electric Pvt Ltd

At Hannover Messe 2024, Elmex Electric Pvt Ltd showcased their broad solutions across different segments, spanning power generation, transformation, distribution, and specialised sectors like mobility and mining. The company intends to increase its international business, which currently accounts for about 30 per cent of its $27 million turnover.

“To a larger extent it aligns to the storyboard we are trying to put forth. So we are looking at specific industry segments to expand our reach. We don’t want to be looked upon as a component manufacturer but truly a solution offering company with our standard components. For any Indian manufacturer, the Gulf is the first footprint where we establish, but now we are spread across 50 countries. We are looking at different markets, on the Micom countries, the far east side of India, also Latin America are some of the major places we are setting our eyes on at the moment,” explained Bhairav Joshi, VP - International Business, Elmex Electric Pvt Ltd.

Elmex Electric, established in 1963, is a leading player in electrical connectivity. Initially focusing on terminal blocks, they have expanded into photovoltaic and energy transformation connectivity. The diverse product range includes solutions for metering, site protection, and low to medium voltage equipment. With recent expansion into the photovoltaic sector, Elmex offers comprehensive connectivity solutions for various applications. The family run business incorporates vertically integrated infrastructure, including an in-house product testing laboratory, ensuring adherence to international standards and versatility across applications.

Joshi added, “Elmex Electric regularly updates the facilities to enhance capacities, including a new factory that will increase production of injection-moulded components, vital for manufacturing all of Elmex’s products.”

Connectwell unveils ambitious growth plans for future

L-R: Manohar Suvarna, VP - International Business & Product Management, and Sandeep Saheta, MD, of Connectwell

Connectwell, headquartered in Dombivli (near Mumbai), is aiming to redefine the landscape of connectivity and automation with ambitious plans for its future. The company stands as a beacon of innovation and reliability in the realm of manufacturing. Established in 1978, Connectwell has continuously evolved, cementing its position as a leading provider of terminal blocks and a diverse array of interfacing solutions. The company has subsidiaries in Brazil, China, and Croatia, and sales offices in Dubai, Saudi Arabia, and Indonesia, Connectwell boasts a global footprint that resonates across 85+ countries.

“Terminal blocks serve as Connectwell's flagship product, boasting the widest range in the industry. From power utilities to rail transportation, machine building automation to infrastructure projects, the blocks are used across diverse sectors. The firm has garnered a core position in the domestic market, with India remaining a pivotal focus,” stated Manohar Suvarna, VP - International Business & Product Management, Connectwell.

While terminal blocks remain the cornerstone, Connectwell's product portfolio also encompasses relay and relay products, interfacing solutions, and a range of switchboard power supply products; the latest innovation: the fan monitoring and control device.

This microprocessor-based device emerges as a game-changer, particularly in high-temperature applications where precise control and monitoring are important. Designed to regulate fans within control panels, this device ensures optimal temperature maintenance, crucial for safeguarding sensitive equipment. Equipped with an RTD sensor and cutting-edge technology, it communicates real-time data, allowing efficient panel management.

“More than 45 per cent of the company’s total revenue comes from exports. Post Covid the company has seen a phenomenal growth in both imports and exports. We have an extremely high double digit growth in our exports market. We will continue to invest in manpower, resources, as well as in geographic expansion. As a group, the turnover would be around $50 million and we expect for exports to increase their contribution to our turnover in the future,” opined Manohar Suvarna.

InPhase to power exports growth with quality solutions

Pannalal Biswas, MD & CEO, InPhase Power Technologies Pvt Ltd

InPhase Power Technologies Pvt Ltd - which designs, develops and manufactures power quality and power conversion products – is eyeing to expand its exports for accelerating its business growth, and Hannover Messe 2024 provided the right opportunity. “Last in the last three years, we have grown at robust pace. By 2025, we want to reach ?1 billion and that is the reason for coming to Hannover Messe to help us expand our exports market as we have proven technology with required European quality certification. Also, because of China Plus One policy, we are witnessing more demand than before for Indian products especially from countries in Middle East and Europe. This is also helping us to expand our overseas business,” commented Pannalal Biswas, MD & CEO, InPhase Power Technologies Pvt Ltd.

InPhase provides power quality solutions ranging from active filters, static VAR generators, hybrid filters, real-time power factor controls (RTPFCs) & automatic power factor controls (APFCs) for customers in India and abroad. “Our energy efficient solutions help in increasing the existing transformer load and enhance the life of the equipment. They can transform the quality of power to suit the process of the industries. Customers witness monetary gains as they consume less energy and reduce their energy bills after installing our equipment,” he stated.

InPhase, which owns numerous patents for its inventions, claims to be the first to launch the largest active harmonic filter across the world and the first 3-level active harmonic filter in India. Biswas informed, “Traditionally, people used capacitor based solutions, which have a lot of inherent problems. Today, industries are opting for process controls, for which the conventional old technology is not suitable. By using InPhase’s ASTRA – a 3-Level insulated-gate bipolar transistor (IGBT) based active harmonic filter - customers are able to optimise their productivity and reduce carbon footprint. More companies are opting for this technology as it provides quality energy solution at affordable prices. We are mainly focusing on the heavy industries, where power consumption is very high. If this technology can work in extreme Indian climatic conditions, then it can work in any part of the world.”

At present, exports account for 10 per cent of the company’s turnover. “We intend to increase exports to 20-30 per cent as there are a good number of opportunities in the global market especially with more industries getting accustomed to this kind of advanced technology,” he added.

Accurate Steel Forgings eyes expansion in new sectors

K Vinoth Kumar, MD, Accurate Steel Forgings India Ltd

Accurate Steel Forgings showcased its range of products with a focus on steel forgings, cushioning materials, brass, copper, and more, at the Hannover Messe 2024. The company specialises in producing forged and machined parts, catering to a diverse clientele of OEMs both within India and overseas. Approximately 50 per cent of the business is geared towards exports. The primary objective of Accurate Steel Forgings at HM2024 was to expand the presence in key sectors such as agriculture, hydraulics, and automobile manufacturing.

Elaborating on their company exports, K Vinoth Kumar, Managing Director, Accurate Steel Forgings India Ltd, commented, “We came to Hannover Messe to increase our customer base. Since last year, we have had a capacity expansion in India to meet the growing market requirement. In this way, we are able to increase our portfolio as well. Europe contributes around 25 per cent to the total exports. As our focus is on increasing the turnover year-on-year, exports (in terms of value) have been on a rise over the years, but its share to the turnover has remained constant.”

Accurate Steel Forgings aims to prioritise incremental growth in turnover, ensuring a steady increase in export value over time.

Opel Energy Systems: Transforming waste into energy

Y D Chavan (right), Founder & CEO, Opel Energy Systems Pvt Ltd

Opel Energy Systems Pvt Ltd specialises in thermal energy conservation and fuel-saving initiatives, leveraging cutting-edge technology to recover heat from exhaust gases exceeding temperatures of 100-150?C, sometimes reaching up to 1,000?C. “Mainly are into waste heat recovery projects, so we have a product called Flux Maxiox, which is a fuel saving device, where one has to install one device in the burner inlet (fuel line) and gets around four to five per cent of savings and we have around 3000+ installations for this product worldwide”, Y D Chavan, Founder & CEO, Opel Energy Systems Pvt Ltd.

While their export portfolio currently stands at 20 per cent, primarily to the UAE with approximately six to seven projects completed, the company expresses ambitions for expansion. “At Hannover Messe 2024, we are looking at associates for our fuel-saving and waste recovery products, particularly due to the convenience and effectiveness of these solutions. This marks a significant milestone for the company, venturing into international exhibitions for the first time in its 50-year history, signalling a clear intent for growth and global partnerships,” said Chavan.

Opel Energy Systems is not just a consultancy; it is comprehensive solution providers, offering end-to-end solutions from concept to commissioning. Its approach involves conducting thorough walkthroughs to assess energy conservation potential, providing proposals, and collaborating with retail engineers to implement solutions effectively.

Opel Energy Systems targets key industries such as process and automobile manufacturing, where substantial fuel consumption is inherent to operations. Chavan elaborates on their role in automotive paint shops, where significant energy is expended in the painting process. By capturing and utilising waste heat from paint shop exhausts, they not only conserve energy but also optimise processes, exemplifying their commitment to sustainable practices.

Hexagon presents smart solutions for quality manufacturing

L-R: Robin Wolstenholme and Alexandre Aime of Hexagon

The Stockholm (Sweden) based Hexagon AB, which primarily focuses on measuring technology and geospatial tools and software, showcased how connected digital solutions can bridge the gap between imagination and reality for manufacturers. Its Manufacturing Intelligence division provides solutions that use data from design and engineering, production and metrology to make manufacturing smarter.

“The manufacturing intelligence division, focusing on industries, offers measuring solutions for different stages from the design and engineering to manufacturing processes, down to designing parts. We also make sure to have a feedback loop into the quality assurance measurement. We follow the flow of the data (i.e. how it is captured, generated, and also used) to empower the manufacturers to take the right decisions and corrective actions on the process to ensure high-quality production,” said Alexandre Aime, VP Global Marketing & Communications, Manufacturing Intelligence division, MSC Software sarl - Part of Hexagon.

At Hexagon displayed ground-breaking innovations in industrial digital reality to enhance every step of the manufacturing process - from design stage to the production line. During HM2024, Hexagon announced partnership with Microsoft to redefine manufacturing with cloud technology. Through this partnership, Hexagon aims to redefine how engineers collaborate and enable the discrete manufacturing industry to innovate faster with new solutions that combine data from virtual engineering processes with real-world measurement of manufactured products. It also displayed the recently launched SmartScan VR800, which is the first optical 3D scanner on the market with a motorised zoom lens that enables users to adjust data resolution and measurement volume entirely through software settings. “VR800 ensures high-precision and saves time of the users,” said Alexandre Aime.

In the recent years, manufacturers in Asia (including India) have been focusing on quality and qualitative production; thus, making them really competitive on the global scale. Hexagon is also eyeing to tap this market with investment in people and innovation. “The company has invested in India, in terms of manufacturing and R&D. We have one of the largest R&D departments in Hyderabad, where we continue to invest as we believe in the talented engineers and people. In terms of market, automotive industry offers a huge opportunity for us. There are machine builders and small & medium enterprises (SMEs) in India who are trying to win global contracts due to shifts in supply chains and the support of the Indian government. Obviously, there is a big opportunity for us and hence we are investing quite a lot in India,” commented Robin Wolstenholme, Global Media Relations and Analyst Relations Manager, Manufacturing Intelligence division, Hexagon.

Teknic Electric capitalises on Make in India wave

Deepak Jaising, Director, Teknic Electric India Pvt Ltd

Teknic Electric, a leading Indian manufacturer of low voltage switchgear and control gear since 1970, is slated for global expansion, and the company leveraged Hannover Messe to connect with potential customers and distributors worldwide. Teknic Electric prioritises meeting international buyers, particularly from Europe, Russia, Africa, and the Middle East through this exhibition. This focus aligns with the China Plus One Policy, where companies are seeking alternatives to China. Deepak Jaising, Director, Teknic Electric India Pvt Ltd, elaborated, “Teknic Electric has seen a surge in enquiries for contract manufacturing, previously dominated by China, from both Indian and international customers. At present, 20 per cent of exports contribute to the company’s turnover.”

To meet this growing demand, Teknic Electric has invested significantly. Its greenfield plant in Goa boasts a 100,000 sq ft constructed area with room for further expansion. Additionally, Teknic has strengthened their tool room facilities, holding shop and assembly line, creating a robust infrastructure for future growth.

“We have developed several new products in the same line as our existing products, for the railways because we see the mandate from the Indian government as ‘See Indian and Buy Indian (‘Make in India’ policy). This is why we also have received a lot of enquiries, not just directly from the Indian railways but also their suppliers. So, big companies have been sending us regular enquiries for products required for the railways. It has been a new focus line,” revealed Jaising.

TexelQ eyes Europe for expansion

G Aswantha Kumar, GM, TexelQ Engineering India

TexelQ Engineering India Pvt Ltd, which provides solutions for machined castings and sub-assemblies, used Hannover Messe platform to expand its global presence by targeting European markets. “TexelQ has a strategic aim to diversify exports with the company's goal of securing a 20 per cent share in the European market, currently dominated by US sales, which constitute 98 per cent of their exports. To penetrate the European market effectively, TexelQ has established a sales presence and navigated language barriers with local representatives, recognising the significance of personal interaction in European business culture compared to the transactional approach prevalent in the US market,” said G Aswantha Kumar, GM, TexelQ Engineering India Pvt Ltd.

Specialising in a wide array of products, including ferrous and non-ferrous castings, forgings, and investment castings tailored to OEM needs, TexelQ has evolved from a design firm in 2007 to a fully integrated manufacturing solution provider through a series of mergers culminating in 2014. While acknowledging India's potential market, TexelQ underscores challenges in supply chain and pricing competitiveness. Their expertise in high-precision machine components extends across diverse sectors, including aerospace, oil and gas, and industrial applications.

Observing shifting industry dynamics, TexelQ sees a trend of manufacturing relocation from China to India. Yet, challenges persist, including the proliferation of shell companies from China in regions like Vietnam, posing competitive hurdles. Despite these challenges, TexelQ has experienced remarkable growth, doubling its revenue from ? 200 million to ? 450 million in the past year, with further growth projected to ? 700 million. The firm aims for stability rather than rapid expansion.

Aswantha Kumar elaborated, “We aim to enter the aerospace sector as it's increasingly accessible in India. However, the challenge lies in adhering to US or Europe government regulations. Hence, our focus shifts to defence and aerospace in the Indian market. We are considering establishing a separate company to streamline operations, ensuring easier collaboration and quality control. This caters to both Indian and export markets, particularly targeting tier 1 company.”

Standard Spring: Crafting global success

Amit Vora, VP, Standard Spring and Metal Pressing Works

Standard Spring and Metal Pressing Works, specialising in the production of high-precision stamping and machining components, is all set to expand its global footprint. In line with its growth trajectory, the company recently inaugurated a new 50,000-sq ft facility in Vadodara, signalling its continued commitment to expansion and innovation. “With an eye on the future, Standard Spring and Metal Pressing Works remains steadfast in its pursuit of excellence, poised to capitalise on emerging opportunities in the global market landscape,” stated Amit Vora, Vice President, Standard Spring and Metal Pressing Works.

The company caters to a diverse clientele, including multinational giants such as Schneider Electric, L&T, Siemens, and ABB in the electrical sector, and Mahindra in the automotive industry. The company adapts its manufacturing processes to meet the unique requirements of each client, ensuring cost-effectiveness without compromising quality. “The company has strategically positioned itself to serve its clientele efficiently. Moreover, its global footprint extends to markets in the US, Germany, Austria, and Dubai, with exports accounting for approximately 25 per cent of its annual turnover, which stands at an impressive ? 800 million this fiscal year,” said Vora.

Looking ahead, Standard Spring and Metal Pressing Works aims to bolster its export figures by a minimum of 5 per cent annually. Participation in international exhibitions, such as Hannover Messe, underscores the company's commitment to expand its global reach and fostering new business partnerships.

Meet you in 2025

From solutions such as the automation of entire production plants, the voice control of machines using AI, the efficient use of hydrogen in industry to the use of software to record and reduce the carbon footprint, Hannover Messe 2024 offered a comprehensive picture of the technological opportunities for the industry of today and tomorrow.

The next edition, in which Canada will be featured as the partner country, will be held from 31 March to 4 April 2025. See you again in 2025!

(With inputs from Sanskriti Ramachandran)

Related Stories

Honeywell, TotalEnergies Advance Industrial Autonomy with AI Control Pilot

By combining operational analytics with real-time predictive insights, the solution supports a more efficient workflow within critical refinery operations.

Read more

Phillips Opens Expertise Centre in Pune to Boost Manufacturing Innovation

New Chakan facility to promote advanced, smart and sustainable manufacturing

Read more

Concord Control Systems Reports 64% YoY Growth in Revenue for H1 FY26

Concord announces strong performance for H1 FY26, with a 64 per cent YoY growth in revenue, driven by increased demand for advanced railway automation solutions.

Read more