Schedule a Call Back

Freudenberg studies the compatibility of sealing materials and cooling fluids

Articles

Articles- Mar 29,23

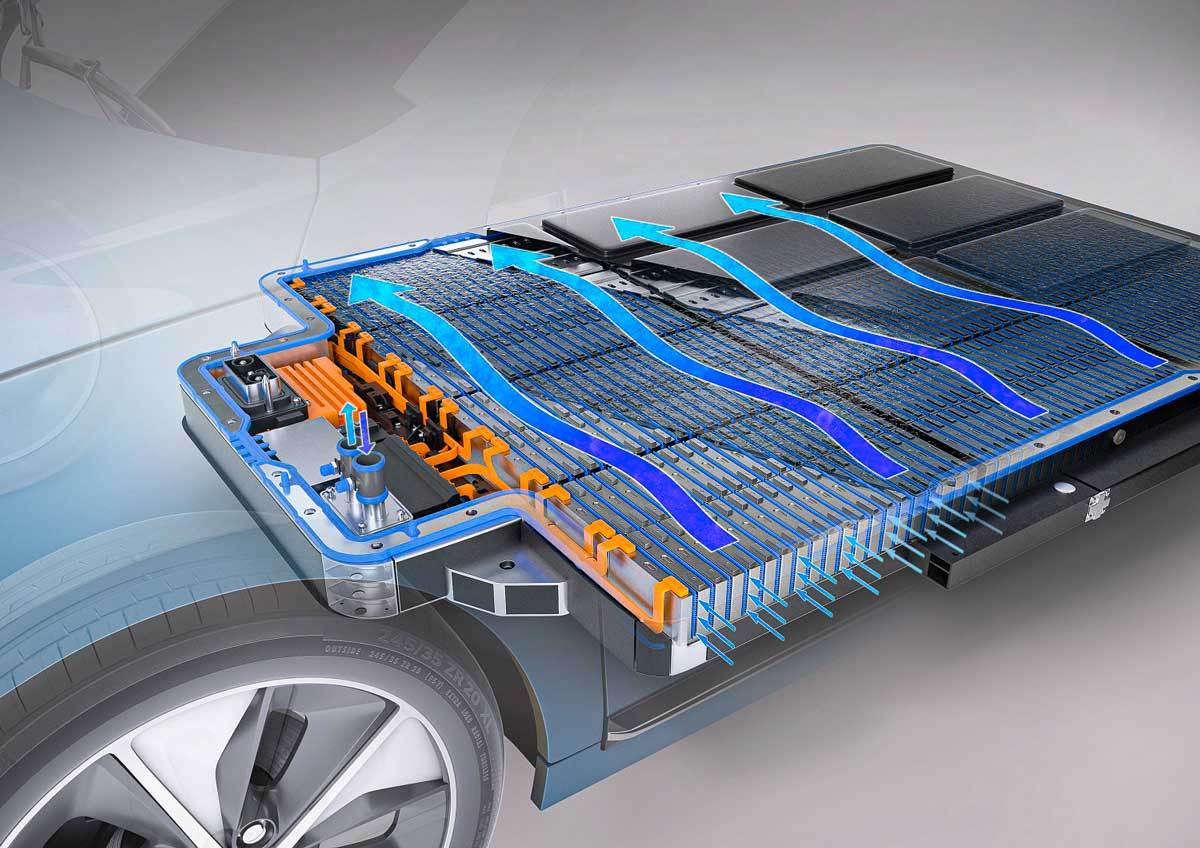

When electric cars are “supercharged” or in cases of extreme power output, the drive battery heats up significantly. The resulting temperatures can exceed the capabilities of common liquid cooling systems. This is countered by innovative cooling strategies in which the battery cells are embedded directly in a specially developed cooling medium that dissipates the heat effectively. In a comprehensive study, Freudenberg Sealing Technologies examined how typical polymer materials used in seals and other components behave inside these kinds of cooling fluids. Freudenberg Sealing Technologies is a longstanding technology expert and market leader for sophisticated and novel applications in sealing technology and electric mobility solutions worldwide.

More and more electric cars can access fresh energy at fast-charging stations. With a charging capacity of several hundred kilowatts, such a station can replenish a battery to 80 per cent within a half hour, for example. The amount of energy flowing into the battery is two or three times higher than when the direction is reversed and energy is released, even under high-performance conditions – for example, when an electric sports car drives on the Daytona International Speedway. As a result, the battery heats up considerably during this supercharging. This can have a negative impact on its power consumption and service life, among other things, if the cooling system is not up to par. Conventional liquid cooling systems that chill entire battery cell systems from the outside are pushed to their limits. That is why automotive manufacturers are increasingly focusing their development on an innovative liquid cooling system that embeds the cells and their electrical arresters in the cooling medium (battery immersion cooling). The medium flows directly around the individual cells and effectively dissipates the released heat.

Analysing the suitability of polymer materials for battery immersion cooling

The cooling media used in these kinds of systems have different chemical properties than those in other prevalent media to date. Their direct cell contact, for example, requires electrical insulation. Vehicle manufacturers are examining several partially innovative substance classes of cooling media with vastly different chemical properties.

As essential components for such cooling systems, sealing elements must have chemical properties suitable for the cooling media. This is also true for components such as fasteners, cell spacers and media storage units. For this reason, and to obtain a broad database for specific customer inquiries, the experts in the Material Predevelopment department at Freudenberg Sealing Technologies performed a comprehensive study to analyse the suitability of polymer materials for media used in immersion cooling systems.

The materials relevant to the company were exposed to various fluids. The tests included is paraffinic oils and ester-based oils, for example, which are specified and widely used for direct battery cooling. In addition to the most conventional fluids, the materials experts also examined the types currently being worked on by the development departments of fluid manufacturers.

Reciprocal effects of materials and fluids

“Depending on the medium, the findings were certainly surprising. The behavior of some new types of fluids differs considerably from that of classic fluids. Nevertheless, we were able to identify suitable materials,” says Dr Tobias Möller, Materials Developer, Freudenberg Sealing Technologies. “Our key questions were: What kind of swelling do the fluids cause in the polymer materials? And conversely, do the materials affect the fluids? The test conditions were challenging.”

Standardised test specimens consisting of the polymer materials were immersed in the fluids for a defined period. To take long-term effects into account and speed up the immersion, the temperature was much higher than is usual and desired for battery systems. The experts then determined the physical key properties of the test specimens that are crucial for the full functionality of a seal over its entire service life, such as volume, weight, recovery behavior, elongation at break and hardness.

“The study provided great clarity. Now we have a comprehensive overview of how the tested polymer materials behave in typical cooling circuits. This is an excellent foundation for the development of future series seals and spacer elements,” concludes Dr Boris Traber, Manager - Global Materials Predevelopment, Freudenberg Sealing Technologies. “Now we also know more details about the fluids. Overall, Freudenberg Sealing Technologies is able to provide substantiated answers to specific customer inquiries and, as usual, can also supply reliable products for this new cooling technology.” He notes that the dynamics in the automotive market have been palpable for a long time. The company is increasingly contacted about immersion cooling for battery systems.

Related Stories

Bharat Forge and Agile Robots sign MoU to Advance AI-Led Industrial Automation

The MoU brings together Bharat Forge’s manufacturing expertise and Germany-based Agile Robots’ AI-led robotics capabilities to accelerate intelligent automation across key civilian industrial se..

Read more

Copper Prices Hit Record Above $13,000 per Tonne

Supply fears and AI-led demand drive sharp rally

Read more

EV transition and tariff wars redefine India’s auto components play

India’s auto component industry is poised to hit $ 145 billion by FY30 from $ 80 billion in FY25. Yet high US tariff, EV transition and heavy reliance on imports from China expose vulnerabilities,..

Read moreRelated Products

Automotive Oil Pump

Kalpak Auto Pvt Ltd offers a wide range of

automotive oil pump.

Tata Motors unveils facilities for development of Hydrogen propulsion tech

Tata Motors, India?s largest automobile company, unveiled two state-of-the-art & new-age R&D facilities for meeting its mission of offering sustainable mobility solutions. The unveilings constitute of Read more

Tata Motors plans petrol powertrain for Harrier and Safari SUVs

Tata Motors is in the process of developing a new petrol powertrain for its premium sports utility vehicles, the Harrier and Safari, as confirmed by a senior company official. Currently, these models Read more