Schedule a Call Back

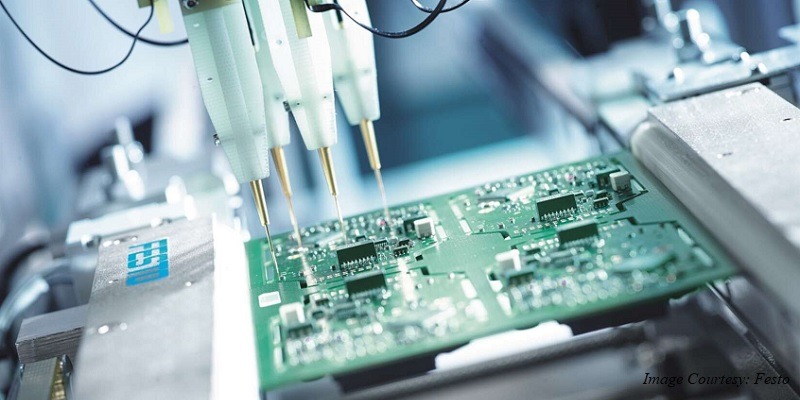

Five of the most popular PCB trends in 2021

Articles

Articles- Jun 18,21

Related Stories

Syrma SGS Begins Work on New PCB Plant in Andhra Pradesh

Syrma SGS has recently started construction of a modern PCB facility in Naidupeta.

Read more

4 Low-VOC Industrial Paints That Deliver High Performance in Tough Environments

Volatile organic compounds (VOCs) - contaminating air and water - can affect health. In this article, Emily Newton explores four high-performance, low-VOC industrial paint options that reduce harmfu..

Read more

ECMS to Boost India’s Local Electronics Value Addition to 40%

The scheme has attracted record investment proposals worth Rs 1.15 trillion, more than double the initial target of Rs 590 billion.

Read moreRelated Products

Integrated Electric Gripper S Series

IBK Engineers Pvt Ltd offers a wide range of integrated electric gripper S series.

Geared Electric Motors

Delco Fans Pvt Ltd offers single phase capacitor run and three

phase geared Instrument motors, totally enclosed face/foot mounted.

“Kusam-Keco” Partial Discharge Acoustic Imager - Model - Km-pdai

‘Kusam-Meco’ has introduced a new “Partial Discharge Acoustic Imager Model KM-PDAI.