Schedule a Call Back

Advanced Optowave helps in medical device manufacturing

Articles

Articles- Feb 10,22

In the recent years, the advancements in new materials and new applications in the medical device world have enabled the industry to produce smaller and smaller devices to offer life-saving treatment options for the aging population. In the recent years, the advancements in new materials and new applications in the medical device world have enabled the industry to produce smaller and smaller devices to treat the aging population.

These new devices are presenting new challenges for the traditional manufacturing technologies to meet the requirements of the new devices and materials. Along with these new devices and new materials is a new regulatory requirement for every implantable device and intravenous drug to have a traceable mark; this unique device and drug identification (UDI) has added to the challenges.

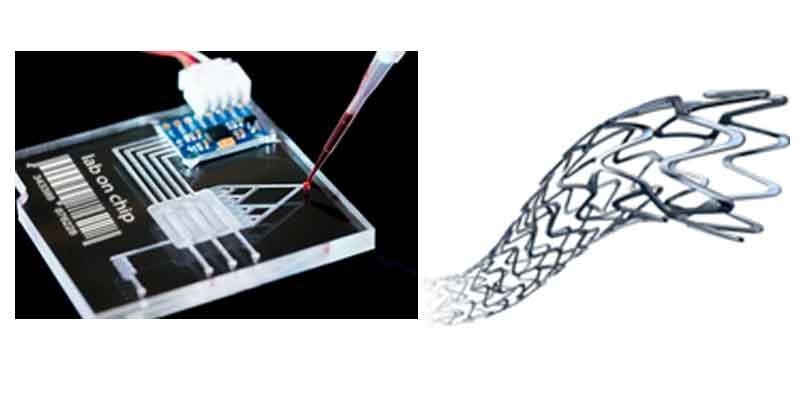

The market requirement for smaller features and/or smaller devices affects passive implantable devices such as Cardiovascular Stents, Neuro-Stents, Bioabsorbable Devices, Transcatheter Heart Valves, Heart Valves, Microfluidics, Transcatheter Aortic Valve Replacement (TAVR), Vena Cava Filters, Lab on a Chip (LOC), Orthopaedic Devices, Bioabsorbable Stents, Intraocular Replacement Lenses, Dental Implants, Cochlear Implants, Ophthalmic implants, Implantable Blood Glucose Monitors, Pain Management Devices, Intelligent Gastric/Cardiac Pacemakers, Implantable Cardioverter Defibrillator (ICD), and Deep Brain Nerve and Bone Stimulators.

Advanced Optowave’s complete diode-pumped solid-state laser product line is well-aligned to help address these challenges, and with the company’s wavelength, energy, and pulse width coverage it has the laser source and experience that will help customers in their R&D efforts all the way through deployment to mass production.

Advanced Optowave’s ultra-short laser product line AOPico and AOFemto are designed to address the challenges the customers are experiencing with these new materials and smaller devices. One of the obstacles customers are running into is part-to-part consistency and yields. Traditional mechanical and traditional laser micro-machining methods are falling short of meeting these new challenges; the A-Thermal machining nature of the AOPico and AOFemto help remove those obstacles.

Additional medical device applications are bioabsorbable polymer stent, heart valve frame, neurological stents, and heat sensitive devices.

With the AOPico and AOFemto, the company’s goal is to offer its customers the ability to work with some of the exotic noble metals that are prominent in the medical device market, platinum, gold, and tantalum and achieve superior results.

Advanced Optowave Corporation prides itself on its consistent ability to meet the strict quality standards that most of the customers face when they are manufacturing medical device components.

Consistency in the manufacturing process and the high-quality of the Advanced Optowave lasers allow it to make sure that high precision hole drilling, small feature cutting of struts and sidewalls, high-quality crack free marking of orthopaedic devices or temper-proof UDI marking of intravenous drugs containers are maintained throughout the manufacturing process and from part-to-part.

Advanced Optowave guides companies, who are developing medical devices, in their projects, be it a prototype or large production run. With its vast experience and wide variety of laser technologies, the company can provide top-notch laser services or laser-based systems.

For details on Adavanced Optowave, contact C. And C. Laser Engineering Pvt Ltd, Mumbai, on Tel: +91 22 4972 7168, Mob: +91 98331 05515, Email: sawant@cnclaserengg.com, or visit www.cnclaserengg.com

Related Stories

Altem organises 3D printing workshop for innovations in medicine and healthcare

The workshop offered a diverse lineup of sessions focusing on 3D printing applications in surgical education, neurosurgery, orthopaedics, and biomedical engineering.

Read more

Medical device sector applauds Centre's Rs 5 billion boost

The medical device market in India, valued at around $14 billion, is anticipated to grow to $30 billion by 2030, underscoring its importance in healthcare, from diagnostic tools to surgical devices.

Read more

Poly Medicure to use Rs 10 billion fundraise for capex and acquisitions

Expansion efforts are underway in areas such as cardiology, critical care, and renal diagnostics, focusing on manufacturing to broaden its market presence.

Read moreRelated Products

Programmable Controllers - Pcd-33a Series

Pro-Med Instruments (P) Ltd offers a wide range of programmable controllers - PCD-33A Series.

Gasket Graphite Powder

Arihant Packing & Gasket Company offers a wide range of gasket graphite powder.

Asahi Kasei expands 3D printing filament sales in North America

Asahi Kasei, a leading resin and compounding technology provider, has initiated the sales of 3D printing (3DP) filaments in North America through Asahi Kasei Plastics North America (APNA). The soft la Read more