Schedule a Call Back

Reimagining sustainability as an attitude for the future

Articles

Articles- Jun 08,18

- Pressure from market: Trade and commercial practices, competitors, customer satisfaction

- Government promotions and regulations: Law enforcement and judicial regulations, private-public participation and accountability

- Economic opportunities: Recurring & long-term financial yields

- Investment in innovation & technology: Technological initiatives for performance enhancement

- Lowering manufacturing cost: Efficient process management with minimum waste

- Improving quality: Innovative process, product quality, enhanced production

- Education and training system: Periodic deployment of training and upgraded technological education

- Attracting foreign direct investment (FDI): Liberalisation of the manufacturing sector

- Infrastructure facilities in transportation sector: Infrastructure development for viable air, rail and road connectivity

- Development in E-economy: Deployment of e-technology in manufacturing sector

- Improving resource efficiency and waste management

- Examining the product life cycle involved in manufacturing

- Trying to ensure economic growth while minimising environmental pollution

- Examining how to stimulate innovation and investment to provide cleaner technology

- Providing awareness and training to employees in sustainability and EHS

- Sustainability measures to ensure sustainable manufacturing across global value chain

- Lack of awareness of sustainability concepts: No or limited access to sustainability literature

- End user adoption: Resistance in end users to adopt the new technology

- Lack of awareness programs conducted locally: No awareness of sustainability trends

- Lack of awareness of local customers in green products: Not enough publicity about green products

- Negative attitudes towards sustainability concepts: Insignificant knowledge of sustainability concepts

- Lack of Environment, Health and Safety (EHS) initiative: Consideration of EHS as cost, no or minimum coordination between departments to maintain EHS data, compliance oriented

- Lack of funds for green projects: Neglected approach for judicious funds distribution

- Lack of standardised metrics or performance benchmarks: Absence of practical guidelines and parameters

- Lack of support from senior leaders: Need for an engaged and committed leadership communicating effectively

- Cost too high: Initial high costs for sustainable technology implementation

- Power shortage: Need for improving present power production and distribution

- Low availability of credit: Need based allocation of funds at low interest rates by banking and financial institutes

- Lack of adopting ICT: India is home to world’s third largest internet users. But ironically India ranks 121st on ICT Development Index 8. Various new technologies like Internet of Things (IoT), big data etc need to be supported

- Legal reform: Most of the laws are very old and out of date. Need to contemporise these out dated laws and regulations

Related Stories

Mitsubishi Electric Invests Rs 2.1 Billion in Chennai Manufacturing Facility

New Chennai plant boosts local manufacturing, capacity and supplier ecosystem under Make in India.

Read more

Sagar Defence Invests in EndureAir to Advance Indigenous Aerial Robotics

Sagar Defence Engineering has announced a strategic investment in EndureAir Systems to strengthen indigenous unmanned and autonomous aerial robotics capabilities for India’s defence ecosystem.

Read more

India must focus on R&D alongside electronics manufacturing: Sanjay Huprikar

In this interview with Rakesh Rao, Sanjay Huprikar, Chief Global Officer of the Global Electronics Association, explores trends in global electronics industry, India’s manufacturing ambitions, and..

Read moreRelated Products

SLMG beverages launches 100% recycled PET Coca-Cola bottles

SLMG Beverages, a prominent company under the Ladhani Group and a franchise bottler for Coca-Cola in India, unveiled a significant initiative by introducing 100% recycled PET bottles for the renowned Read more

Mineral Water Plant

Richa Environmental Services Pvt Ltd offers a wide range of Mineral Water Plant.

Read more

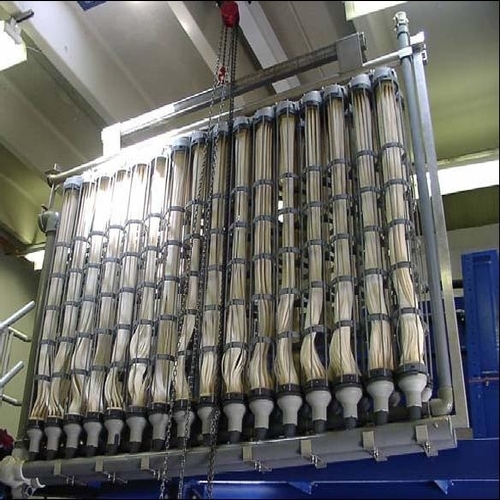

Membrane Bioreactor MBR

They offer high quality Membrane Bioreactor used for industries for their sewage treatment plants , effluent treatment plants.The MBR process involves a suspended growth activated sludge system tha Read more