Schedule a Call Back

New FMS versions - control in every situation

Interviews

Interviews- Jul 01,17

JAKOB Antriebstechnik now offers its Force Monitoring System ‘FMS’ in three different versions.

The new types expand the application areas of the FMS enormously, also by the scalable design, and offer safety for man and machine as well as increased processing quality. The ‘FMS Jaw XXL’ offers a force monitoring system integrated into the clamping jaw and is versatile applicable. The ‘FMS Jae S’, on the other hand, is a miniaturised version in which the FMS is integrated in a special clamping jaw which can be placed on a standardized clamping device instead of a conventional jaw. The third version is the ‘FMS Pad’, which is used for processing large parts. Here it is inserted between the clamping element and the workpiece.

All versions can transmit their measured values wirelessly to different devices, such as a hand-held display with multiple clamping force indicators or directly to a machine control. Thus, an emergency stop can be carried out in the event of a sudden drop in force. Depending on the design, the measuring range is recorded from 0-1000 kN.

How the FMS works in detail:

When working on large workpieces which are tensioned using face plates or jaw boxes, enormous clamping forces must be ensured depending on the workpiece. Particularly in the case of workpieces with a multi-day clamping time and numerous shift changes, monitoring of the clamping forces is absolutely safety-relevant. Sufficient clamping forces are also crucial for ensuring a high quality of processing.

JAKOB drive technology offers intelligent clamping jaws, with which these forces can be reliably monitored even during processing by constant data transfer. The force measurement is carried out using strain gauges. In the event of a decrease in the clamping force, the Force Monitoring System (FMS) can be set up in a way that an emergency stop signal is sent to the processing machine, and the processing can be interrupted reliably and in a timely manner. The user can, of course, freely adjust the limiting force, when the system triggers. Depending on the design, the measuring range is between 0 and 1000 kN. Previously available systems, whether working statically or dynamically, are not able to reliably and precisely detect the actual clamping situation.

The FMS from JAKOB Antriebstechnik transmits the evaluated data wirelessly and enables it to be displayed via a handheld display device included in the scope of delivery, a standard notebook or its transmission directly to the machine control, whereby logging is possible over a longer period of time at regular intervals. The hand-held display is powered by a built-in rechargeable battery, which can be recharged in its docking station.

A combination of FMS and power clamping spindles from JAKOB Antriebstechnik ensures maximum clamping forces with minimum tightening torque, while at the same time ensuring the highest safety and processing quality.

Related Stories

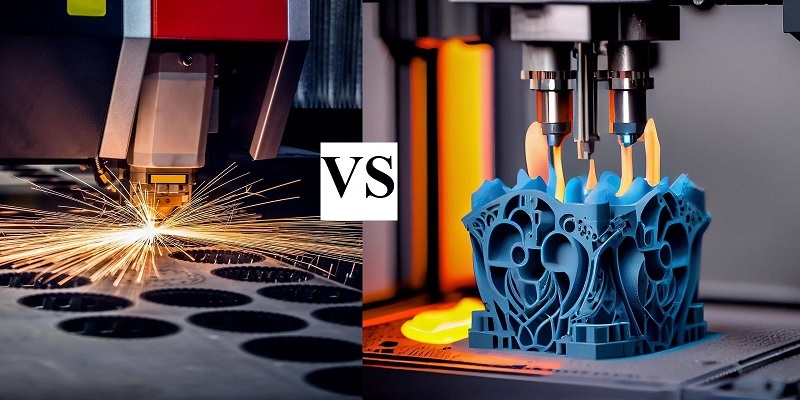

Intersection of 3D printing and laser cutting: A new paradigm in manufacturing

The intersection of 3D printing and laser cutting remains a niche area. However, it should gain prominence when people learn about use cases that demonstrate versatility and viability, says Emily Ne..

Read moreJindal Aluminium produces 115,920 MT of aluminium extruded products in FY23-24

Operating three cutting-edge manufacturing plants located in Bengaluru, Dabaspet (Karnataka), and a newly acquired facility in Bhiwadi (Rajasthan), Jindal Aluminium boasts a total manufacturing capa..

Read more

Zoho plans $700 million foray into chip manufacturing; compound semiconductors

Semiconductors occupy a pivotal position in India's economic agenda, with the government implementing a $10 billion package to fortify the industry's capabilities, positioning the nation to rival es..

Read moreRelated Products

Breath Alcohol Analyser DBAN Pro

Subtronics (India) Pvt Ltd offers its innovative breath analyser, model: DBAn Pro, which is designed to check the presence of alcohol in breath. DBAn Pro displays the presence of alcohol and alerts Read more

Oxygen Monitor (Portable):deficiency + Sufficiency

Subtronics (India) Pvt Ltd has innovated its latest oxygen monitor model OXYn designed to monitor the presence of oxygen in ambient air. Read more

Sentinel Analyzers

Steam Equipments Private Limited offers Sentinel Analyzers. Teledyne offers two proven standard sensor configurations as functioning receptacles for its Oxidation Reduction Potential (ORP) cartridg Read more