Schedule a Call Back

Refrigerant evolution: Tackling HFC to HFO transition challenges

Articles

Articles- Jan 09,24

- Developing a National HFC Phase-out Plan: This plan outlines a roadmap for transitioning from HFCs to HFOs, including refrigerant quotas, phase-out schedules, and financial incentives for HFO adoption.

- Government and industry bodies like BIS (Bureau of Indian standards) are working to harmonise international standards with Indian standards like ISO /IEC 60334-2-40, the guideline for implementing A2L refrigerant that can pave way to usage of HFOs

- Promoting HFO Technology: The government has established a dedicated HFO task force to promote research and development of HFO technologies and support the transition for Indian manufacturers.

- Training and Certification Programs: The government and NSDC (National Skill Development Corporation) provide training programs for technicians and engineers on safely handling and servicing HFO-based equipment.

- Financial Incentives: The government offers financial incentives such as subsidies and tax breaks to encourage the adoption of HFO technologies by companies and individuals.

Related Stories

EXCON 2025 Sets New Benchmarks for India’s Construction Equipment Sector

EXCON 2025 set new benchmarks in scale and participation, reinforcing India’s position as the world’s third-largest construction equipment market and showcasing the sector’s readiness for sust..

Read more

Knauf India doubles capacity with new metal line at Khushkhera plant

The increased production capacity is expected to improve the company’s ability to meet rising domestic demand and support a wider portfolio of drywall and ceiling solutions.

Read more

Jindal Stainless Posts DJSI ESG Score of 78, Ranking among Top Global Steel Players

Jindal Stainless has achieved an ESG score of 78 in the DJSI Corporate Sustainability Assessment for FY25.

Read moreRelated Products

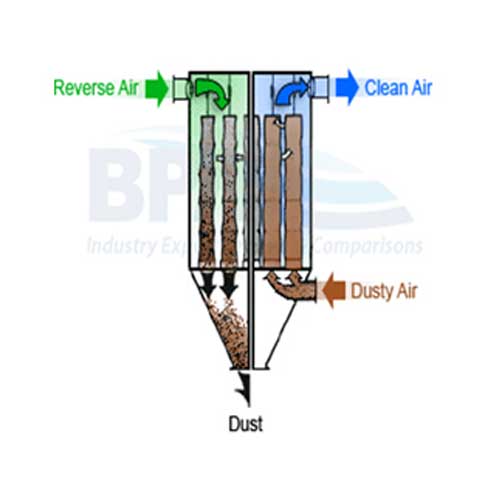

Reverse Air Bag House

ABR Enviro Systems offers a wide range of reverse air bag house.

High Quality Air Knife System

Superchillers offers high quality air knife system. Read more

Compact Cylinders -Vadvu Series

Vijay Air Control offers a wide range of compact cylinders -Vadvu Series