Schedule a Call Back

External Wear Liner

External Wear Liner

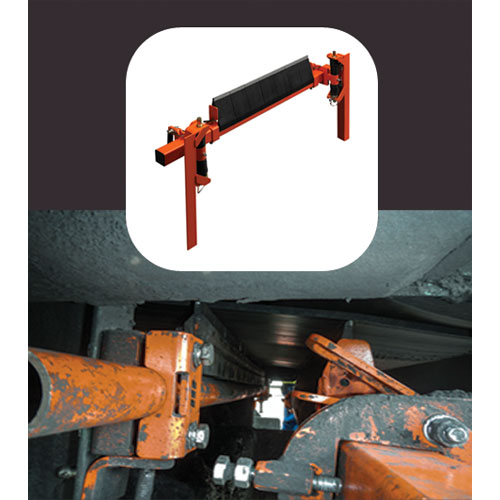

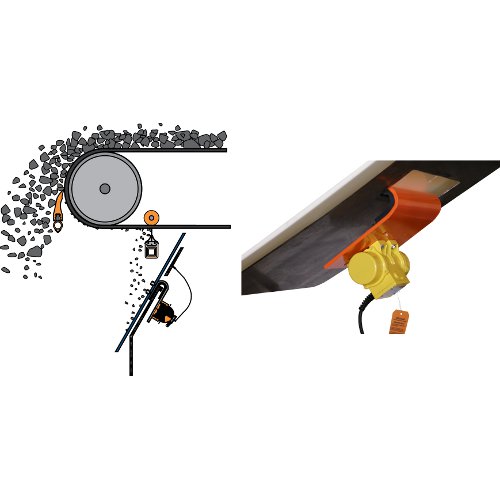

Martin Engineering, the world leader in making bulk materials handling cleaner, safer and more productive, offers new External Wear Liner. The company has redesigned an integral conveyor transfer point component to eliminate worker entry into the chute box for safer replacement, easier maintenance and reduced downtime. Conventional wear liners have historically been installed inside the chute, but the EVO® External Wear Liner is placed on the outside, improving skirtboard sealing and preventing spillage. The result is excellent performance with fewer labor hours and a lower cost of ownership. Previous designs securely welded the wear liner to the inside of the chute, with only the skirt seal located on the outside. The logic behind the conventional design is for the wear liner to protect the skirtboard, which is typically ¼ inch sheet metal and not strong enough to withstand the sustained force and abrasion from bulk material. Instead, Martin Engineering designers came up with the idea of raising the chute work about 4†above the belt, out of the way of the material, then putting the wear liner on the outside. Using this approach, the material still hits the liner and doesn’t damage the chute. After elevating the chute box above the material flow, a 3/8" or 1/2" (0.95 cm or 1.27 cm) thick abrasion-resistant liner plate (AR 400 or 500) is mounted on the outside of the chute, followed by the skirt seal. Mounting brackets with jackscrews provide a tight hold, with precision adjustment of the wear liner to reduce spillage. This system closes the gap between the liner and the sealer, thus eliminating abrasion from trapped material without interfering with existing supports. When accompanied by Martin Double Sided ApronSeal™ skirting and clamps, the system forms a tight belt seal, delivering outstanding fugitive material control.

Products from Martin Engineering Company India Private Limited

Preventing Buildup in Conveyor Discharge Chutes

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads