Schedule a Call Back

Wet Scrubber

Wet Scrubber

Anil (Air) Pollution Controllers high efficiency Wet Scrubber, Model Cyclo-Swirl. This is a 3rd generation wet scrubber, which was originally developed to serve the sugar, pharmaceutical and similar industries. The Cyclo-Swirl, scrubbers are now successfully adapted for fly-ash application to comply with the latest pollution control norms. The ‘Cyclo-Swirl’ scrubber adapts following cleaning stages: in the first stage, the contaminated air enters the scrubber tangentially which forms a cyclonic pattern around the centrally located ‘multi-slot cage’ the water fountain is introduced by open pipe at nominal pressure in the centre of the cage. The air tries to pass into the cage in cyclonic pattern, were the water fountain is disturbed, and tries to escape outwards from the slotted cage; the combination of these two actions creates the turbulence, breaking the water into large droplets and at the same time high velocity centrifugal force is created. The course dust particles impacts with large water droplets and the saturated particles are removed from the stream by cyclonic action. In the second stage, the contaminated air/water once passed into the ‘multi-slot cage, it creates atomised inner cyclonic vortex. These combined actions create the scrubbing efficiency. The contaminated water is made to escape from the base of the ‘multi-slot cage’. In the third stage, the cleaned air is made to pass up-wards, into the ‘vortex section’ where the cloud of fine water droplets are made to spin and collected water is dispelled into the bottom hopper. Whereas the moisture contained clean air is directed into the ‘expansion chamber’ where the air velocity is reduced drastically, which provides the required contact time for removal of mist and any uncollected submicron particles before expelling the cleaned air into atmosphere via existing chimney. These combined cleaning actions give high collection efficiency when compared with conventional scrubbers. Due to simple and open construction of internal components it can be made from any material and can be coated against abrasion and chemical reactions. The collected slurry management to suit site requirement can be offered which include automatic slurry separating conveyor system, rake out type of water tank or the open pit discharge

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

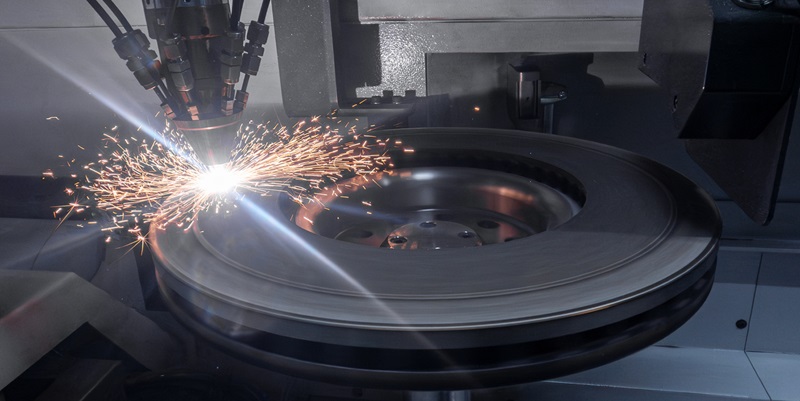

Versatile Machining Capability Through Ram Type Milling & Grinding Heads