Schedule a Call Back

Washing Machine for Cylinder Halves

Washing Machine for Cylinder Halves

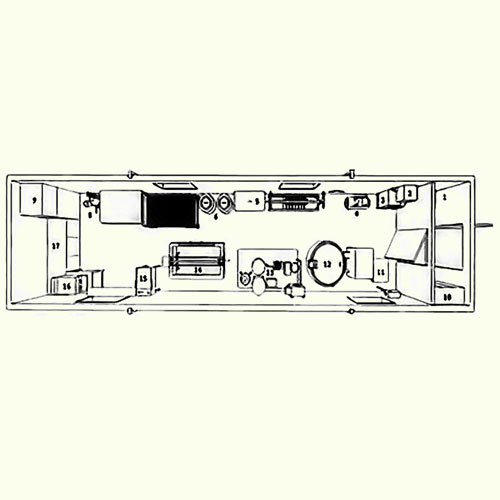

SS Engineers & Consultants has introduced a Cylinder Halves Washing Machine for factories engaged in mass cylinder manufacturing. Over the years the company has developed many cleaning machines to clean various types of industrial products and component cleaning, suitable for factories having continuous production. These machines have been developed to meet the challenging cleaning requirements of the customers.

The LPG cylinder halves degreasing/cleaning machine features three wash zones operated through individual pumps, and the user has access to operate the machine with different chemicals/alkalis in the first two chambers; the third chamber is for neutralising the product with hot or cold water, thus removing the surfactants from the product surface.

The machine is designed to recycle the chemical water, which is used to clean the cylinder halves through pressure jet washing system pump. The cylinder halves are loaded manually to the machine carried through a link chain conveyor allowing them to pass through all the three washing zones.

The machine features a steam heating system to heat the water to the required temperature for effective cleaning results. This cylinder halves cleaning machine comes with an option of hot air drier operated through steam or electrical heating elements. The air is heated up to 120°C and blown off to dry the cylinder halves online after the water bath.

The LPG cylinder halves cleaning machines are available in two capacities:

- 800 halves cleaning/hour

- 400 halves cleaning/hour

- Complete machine made up of SS 304 material, including conveyor belt

- Low water consumption, one time filling to clean 8000 cylinder halves (per day)

- Continuous washing system, heavy-duty geared motor and SS pumps

- Recycling and re-use of water with 3-stage filtration

- Semi automatic electrical panel board with instrumentation for easy operation/control

The company uses mild steel sheet everyday for a vast range of sheet metal work for the benefit of customers. But, the majority of sheet metal products manufactured from mild steel have high amount of carbon within its structure, which makes mild steel prone to corrosion (rust). For those customers who need rust free sheet metal steel product, surface finishing/treatment is needed.

The LPG cylinder halves cleaning machine removes 5 kg of carbon during 10 hours of operation. This is a very good amount of carbon removal by any machine or system.

Product & Technology News

Products from SS Engineers & Consultants

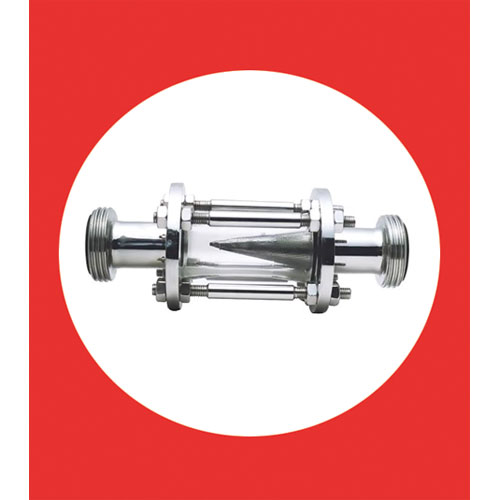

Stainless Steel Filters (Sight Glass)

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads