Schedule a Call Back

Slip Rings And Commutators

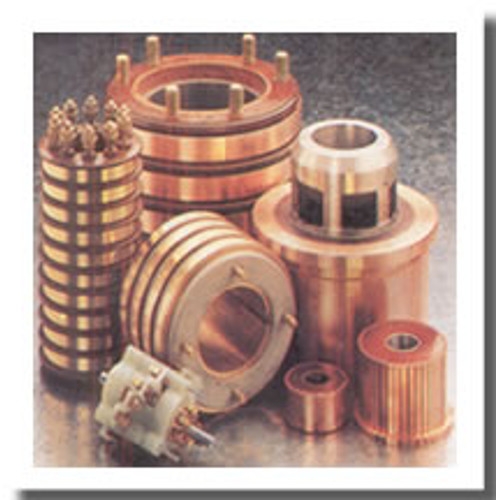

Slip Rings And Commutators

National Carbon Brush Products offers Slip Rings And Commutators. In principle commutator insulation should be recessed below the surface of the segments, unless hard carbon brushes are used. Segment edges should be bevelled to ensure on the one hand proper communication and on the other to avoid high brush wear or brush breakage. Commutators and slip rings should have a true round form otherwise contact will be interruped at high speeds and brush sparking may occur. Small irregularities can be removed by means of commutator hand stones pressed lightly on commutators or slip ring when running. In case of eccentricity, however, the commutator or slip ring must either be turned or ground, if possible at full speed in its own bearings. Brush spacing should be as exact as possible particularly on high speed machines with difficult commutation. Brush spacing can be checked by means of a paper strip cut to length of the circumference of the commutator or slip ring. The paper strip is marked in equal spaces with the brush positions corresponding to the number of brush arms. It is then wrapped round the commutator and the position of the brush holders may be checked and adjusted if necessary (the leaving edges of the brushes are used for this adjustment). The brush on one brush arm must be exactly in line, except for any internal brush stagger. While fitting brush holder the gap between the lower edge of the brush holder box and the surface of the commutator or slip ring should not exceed 2 mm to 2.5 mm, also, the brush holder edge and the collector surface should be parallel. Radial brush holders should be fitted in an exact radial position. In case of reaction brush holders, with brush inclined 30o, the brush holder must be fitted at the correct angle, with the commutator revolving towards the sharp angle of the face. In the case of trailing brush holders inclined at 8°, the commutator revolves away from the sharp angle of the brush.

Product & Technology News

Products from National Carbon Brush Products

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads