Schedule a Call Back

Crimped Wire Brushes

Crimped Wire Brushes

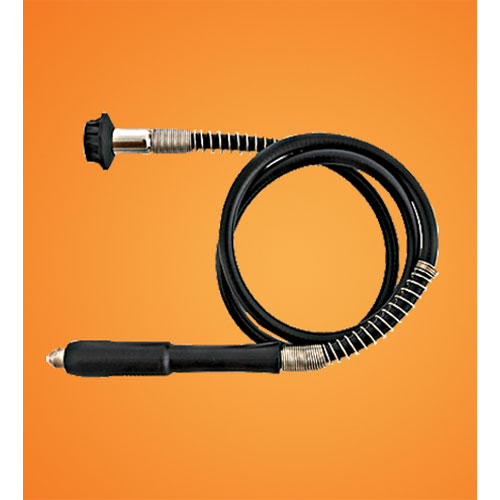

A M Associates offers crimped wire brushes.

- The crimping of crimped brush wires allows the bristles to better support each other than straight bristles

- Crimped wire brushes are less aggressive than knot type, and best for light to medium cleaning and material removal; two main factors create performance variations between crimped wire brushes: brush width and steel hardness

- As discussed above, increased face width will produce more aggression; for wire brushes, steel hardness is usually measured on the Rockwell scale, which measures the ‘indentation resistance’ of materials

- Rockwell hardness measurements are abbreviated ‘Rc’, followed by a hardness number. Most crimped wire brushes are manufactured with steel between Rc 30 and Rc 60; the higher the Rc measurement, the harder the steel.

Products from A M Associates

Verified

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Verified

Verified

Versatile Machining Capability Through Ram Type Milling & Grinding Heads

Deburring, Drilling, Boring, Tapping and Threading Machines

Verified

Verified