Schedule a Call Back

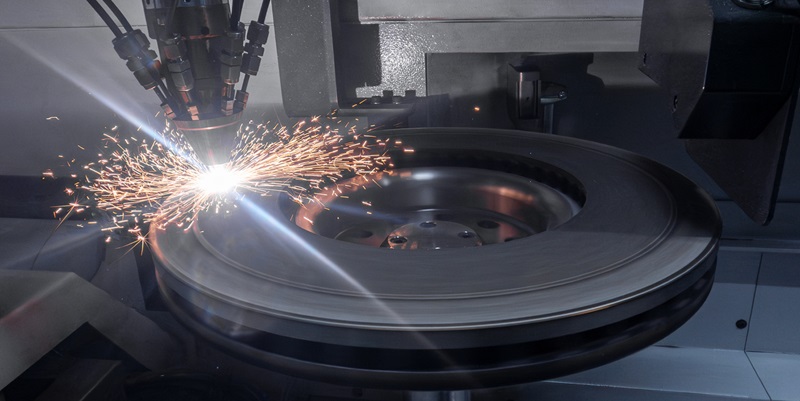

High Precision Alignment System

High Precision Alignment System

Diamant Triumph Metallplastic Pvt Ltd offers a High Precision Alignment System, DWH, for joint faces in machines and machine tools, which eliminates costly machining by using the moulding technique. These techniques allow an in-place moulding to a precision down to the micron with an exact replica of the tool surface. The material can be either caused to stick to the moulding surfaces or released by the inclusion of a micro thin layer of Diamant separator liquid.

Roughen adhesion areas down to a roughness of 0.3-0.5 mm and then clean chemically (optimum: Diamant cleaner). Make sure that the working temperature is in the acceptable range of 20°C ±10°C. Pour the hardener liquid fully into the resin container. Mix manually by spatula or by machine (100 rpm for 2 min) until the hardener liquid is mixed well with the resin. Ensure that material adhering to the side walls and the bottom is well incorporated. Apply a thin adhesion layer and push it into the surface using a spatula. Add the remainder taking care not to trap air. Pour DWH in the prepared cavity slowly in a long, thin stream. Aim at the lowest point to fill from the bottom and thus avoid the entrapment of air, or pump the liquid in from the bottom of the prepared gap using a pump cartridge into a prepared inlet port. To achieve coverage on larger components a number of inlet ports may have to be established. Ensure that the application is made safely within the pot lifetime.

- All Types of Gantry Machines

- Joints, Spindle Shafts, Key Slots

- Guide Rails, Bearing Chairs And Flanges, Machine Beds

- Bearing And Index Bushes, etc.

- High accuracy

- High load carrying capacity 170 n/mm2 (static)

- Excellent shock attenuation

- Full contact of mating surfaces and therefore good load transmittal

- High load carrying capacity

- High damping properties

- Good adhesion with nearly zero ageing or weathering

- Precision down to the micron without expensive machining or finishing work

Products from Diamant Triumph Metallplastic Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads