Schedule a Call Back

Wire Harness Engineering: From Schematics Through To Production

Wire Harness Engineering: From Schematics Through To Production

Version 2.5 of Eplan Harness proD is in the start blocks. In combination with Eplan Platform's central parts management system, users benefit from continuous and optimised workflows. A wide range of enhancements for nail board design, cable routing and project management guarantee effective wire harness engineering.

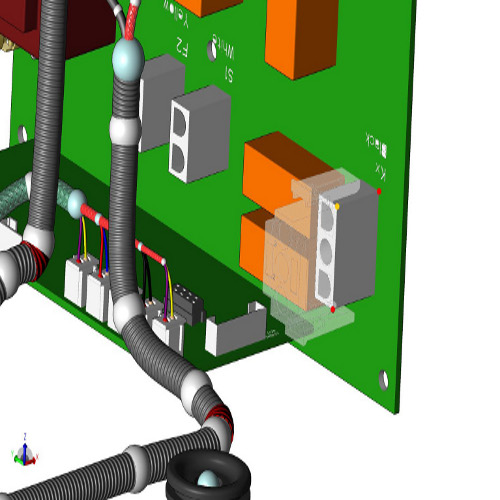

Version 2.5 of Eplan Harness proD is available from October 2015. Development has focused on optimising user workflows and a major new highlight is the coupling of the 3D wire harness engineering system to the Eplan Platform's central parts management. This represents a milestone in integrated data management. Users then have only one central parts management system, which they are able to access over the entire course of a project. This significantly reduces the effort in maintaining master databases and enables continuous workflows from schematics through to production documentation. Master data workflows have been further optimised through the derivation of 2D symbols – required for nail board drawing – from existing 3D data. This is particularly efficient because 3D component data is already required. Existing data therefore gets reused – manual creation of component symbols is unnecessary

Simple component positioning in 3D

Eplan Harness proD aims to provide a user-friendly 3D system for wire harness design. Electrical engineers generally have limited experience in operating complex MCAD systems and therefore benefit from a user-friendly approach. For example, by positioning a component, such as a connector, within the 3D space enables the selection of reference point, edges and areas. This simplifies the positioning process. A preview function helps users to achieve correct positioning at the first attempt avoiding the need for subsequent adjustment. Users who use AutoCAD symbols can look forward to a much improved import function. Imported DWG and DXF drawings can be edited in Version 2.5 with all the relevant content being extracted. This greatly speeds up the process of creating parts.

Faster cable routing

Version 2.5 of Eplan Harness proD includes many new features – for example, the fixing of a 3D object's positioning, the option to position the starting point of a new bundle in a wire harness into existing bundles, and the automatic routing of cables. To support production, wire colourings can be displayed in the connector symbol on the nailboard. Production can then use the drawing to identify the correct positioning of a wire at a connector. Searching wire lists for the necessary information is no longer required and the production process becomes faster.Flexibility in nailboard design

There are also many new features in the nailboard design to interest users. Eplan Harness proD 2.5 has separated the "data layer" from the "display layer". This might sound technical but it gives users massive flexibility in nailboard design. Display configurations enable a drawing to be viewed differently without having to change the data – e.g., according to a company's internal drawing standards. This gives greater flexibility. Batch processing of updates has been added to project management section of Eplan Harness proD. The need for evaluation or drawing updates is detected and then batch processed to further reduce project management effort. Features such as the automated updating of library parts or the newly supported CAD formats are among the many enhancements to increase the efficiency of wire harness projects and to speed up customer workflows.

Products from Rittal India P Limited - EPLAN Division

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads