Schedule a Call Back

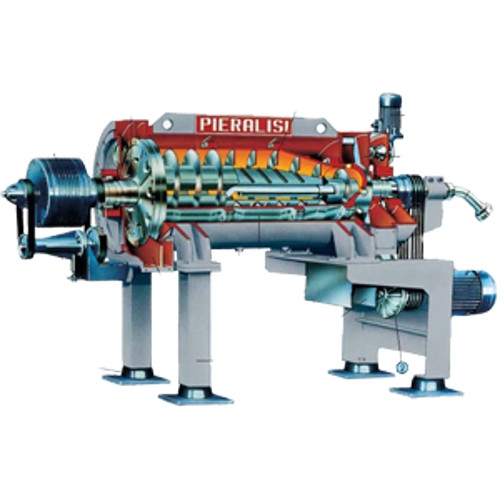

Pieralisi Centrifugal Decanter

Pieralisi Centrifugal Decanter

Auric Techno Services Pvt Ltd offers Pieralisi Centrifugal Decanter. Pieralisi Decanter Centrifuges & Disc Stack separators , clarifiers, are extensively used for solid-liquid, liquid-liquid and liquid-liquid-solid separations, based on the difference in the densities of the various components, using centrifugal force for carrying out the separation of phases. These equipment are designed for continuous 24/7 operation and are used across wide industry segments viz. Fruit & vegetable processing- for clarification of fruit pulps & juices, Dairy- milk & whey clarification/ separation, Fat rendering, refineries for slop oil treatment, Industrial and Municipal sludge dewatering, Edible oil, Olive oil, Pharmaceuticals & Biotechnology- Fermentation broth separation/clarification of various process liquids/biomass separation, and many other sectors. Decanter Centrifuges & Disc Stack separators are available in all type of Stainless Steels, and alloy steels, and are also supplied as Gas Tight and explosion proof construction, depending upon the requirements. The Decanter Centrifuges & Disc Stack separators are available for capacities ranging from 1 m3/hr to 100 m3/hr. The decanter centrifuges can be supplied as per process requirements in various grades of Stainless Steel, and in Gas tight versions with inert gas purging and also for explosion proof area installation.

- Open Scroll: A unique feature of Pieralisi decanter. The scroll has four slots, at 90° with each other, across the complete length.

- The feed can thus enter the bowl at any point, based on location of shuttle feed pipe. As a result fine-tuning of operation for optimization of results is achieved.

- (Almost all other decanters have four holes or very small slots at 90° with each other, but at one specific location. Hence the feed can enter the bowl at only one location. As a result fine-tuning of operation, spraying water for dislodging of choked solids across the entire length of machine is not possible).

- Removable Shuttle feed pipe: Another unique feature of Pieralisi decanter. The feed pipe can be moved over a considerable distance, within the bowl, while the decanter is in operation. As a result the retention time, inside the bowl could be precisely adjusted, for optimization of results.

- Scraper mechanism: A patented feature of Pieralisi decanter. The separated solids are discharged from the bowl, through solid discharge ports under a high ‘G” force. These solids strike the inner surface of sediment chamber and fall down through cake discharge chute. But when the solids are sticky and fibrous they do not fall down easily, but tend to stick to the wall. A built up of solids thus occurs inside the sediment chamber, which reduces the quantity of solids discharged from the bowl.However, solids continue being separated inside the bowl and are being conveyed to the solids discharge ports. As the discharge of the solids is prevented because of the built-up in the sediment chamber, the solids start building up inside the bowl itself. The bowl shortly gets choked with solids and the decanter just stops functioning. Cleaning of such choked solids is a daunting task, which takes several hours, lot of manpower and of course production loss.This does not happen in a Pieralisi Decanter. The Pieralisi decanter is equipped with a scraper mechanism, a patented feature. The scraper mechanism rotates a blade at slow speed, inside the sediment chamber and scrapes all the solids, sticking inside the sediment chamber, preventing any buildup of solids. This avoids the problem of choking, which is observed in many other makes of decanters, in the industry.

- In an unforeseen situation (i.e. unforeseen for Pieralisi decanter) of choking of bowl by accumulated solids, due to operators error or process upsets, it is possible to dislodge the choked solids without opening any component. Simply remove the shuttle feed pipe from the decanter and insert a ‘high pressure’ water hose into the decanter. The spray is directed between two consecutive flights of the scroll from near the solids discharge end and slowly moved further inside till the solids are dislodged. Restart the decanter. The unforeseen situation can thus be rectified in no time.

- The above features, together, virtually eliminate requirement of standby machines, in most of the cases.

- Pieralisi decanters have many other features, which make them an ideal choice for solid-liquid separation needs for the processing industry.

Products from Auric Techno Services Private Limited

Pieralisi Disc Stack Separator

Teknofanghi Poly Dilution Unit

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads