Schedule a Call Back

Hot Nozzles

Hot Nozzles

Sarvesh Engineering offers Hot Nozzles, SEHN16/20. It is used for existing cold runner molds. It can be installed on the existing cold runner easily, with a minor rework on the back plate and cavity plate / cavity insert. Expected down time for the re-work is one shift/one operating day. With introduction of nozzle, the polymer is kept heated right up to the point it is injected in the mold. It keeps the polymer heated right up to the injection point giving advantages like injection pressure required for filling the mold is reduced drastically, there by reducing the energy cost, savings in the power consumption by motor, runner-less molding, savings in raw material cost and reprocessing cost of runner generated, improved quality of molding due to uniform filling and shot to shot consistency. Detailed drawings for the rework will be given to enable do the necessary re-work in house / locally.

Products from Sarvesh Engineering

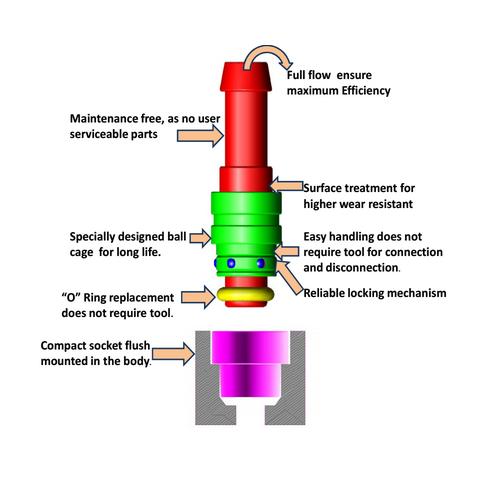

Quick Connector for Water & Air Application

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads