Schedule a Call Back

Ultrasonic Sieving Attachment

Ultrasonic Sieving Attachment

Conventional sieving technology is based on a vibrational/wave motion of the sieve. This action is responsible for the sieve throughput as well as the separation of oversized material. In addition to the conventional method, Sonoscreen ultrasonic supported sieving technology evenly transmits as oscillating motion, in the micron range, onto the screen surface. This feature reduces friction between the sieve mesh and bulk material. Depending upon the particle structure this reduction can result in a significant increase in throughput volume. Screen blinding and clogging are also reduced due, to the cleaning effect the oscillating motion has on the sieve mesh. A consistent, efficient production process in guaranteed while simultaneously reducing the related maintenance costs to a minimum. Sonoscreen can be applied to both wet and dry sieving applications. System components for the sieving installation: Sonoscreen can be built into or retrofitted to all existing commercial sieving equipment. The Sonoscreen system components include: ultrasonic generator – a complete electronic unit that can be attached directly to the sieving machine, or mounted on a nearby wall; ultrasonic sieve resonator – consists of a converter with ring resonators which are connected to the sieving frame with mounting plates, HF-electrical connection with housing and plug; and HF-connector cable – standard length 3m/10 ft connects the ultrasonic sieve resonator to the ultrasonic generator.

Products from Roop Telsonic Ultrasonix Ltd

Sieving Technology, Ultrasonic Supported

Ultrasonic High-Power Sono-Processor

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

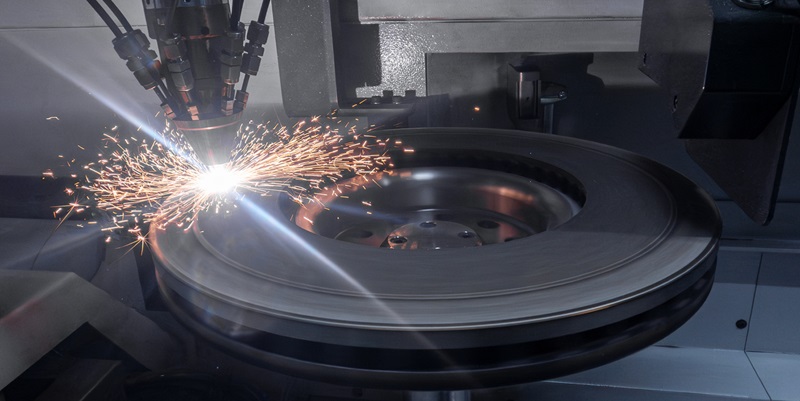

Versatile Machining Capability Through Ram Type Milling & Grinding Heads