Schedule a Call Back

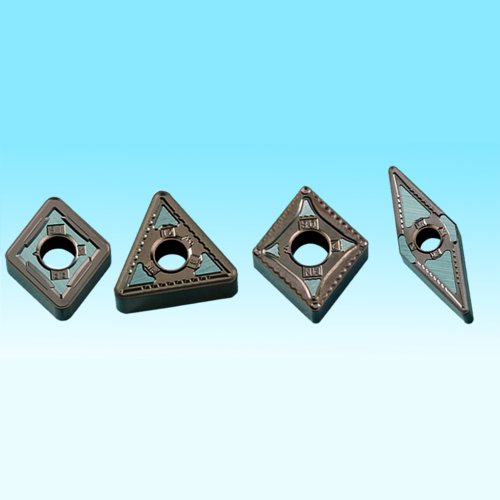

Cutting Tool Inserts, Beyond Drive

Cutting Tool Inserts, Beyond Drive

Kennametal has launched new Beyond Drive™ Cutting Tool Inserts with bronze TiOCN top coating that increases wear resistance and functions as a wear indicator. These inserts are helping component suppliers expand and thrive in this environment with enhanced performance and extended tool life that mean many more finished pieces per cutting edge. Specifically designed for cast irons, steels, and stainless steels that make up many critical components over a variety of industries, Kennametal’s new Beyond Drive inserts are a product of ongoing design leadership, engineering, materials science, and manufacturing directly targeted to the needs of component manufacturers. With Beyond Drive, adding a new titanium oxy-carbonitride outer coating (TiOCN) not only increases wear- and abrasion-resistance, its bronze colour is also an effective wear indicator. Depending on the application, field tests are showing anywhere between 30 percent and 125 percent more parts per edge. All new Beyond inserts are CVD (chemical vapor deposition) coated, but whereas conventional CVD coatings are under tensile stress, Beyond inserts undergo a proprietary post-coat treatment on all surfaces to reduce this stress, which improves coating adhesion and reduces micro-chipping. Beyond Drive is available in eight grades and numerous insert styles, covering a complete range of applications for turning steel and cast iron components.

Product & Technology News

Products from Kennametal India Limited

Solid Carbide Drills Hps Aluminium Type

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads